Features of sharpening hunting knives

A hunting knife is not just a tool for solving everyday tasks and sanding. It is an eternal companion and a source of pride for every hunter. The knife should always be clean and sharp. The sharpening angle of a new knife is optimal, the tool can last for quite a long time, but deteriorates over time: microcracks appear, sometimes even notches, in addition, it can simply cease to be sharp. Only sharpening can cope with this problem.

About steel and properties

An experienced owner of such a knife will never use it for other purposes in order to avoid damage and complete failure. The knife must always be clean. The contact of the blade with an aggressive environment is unacceptable: this contributes to oxidation. All these simple precautions will help save the knife and keep sharpening for a long time.

It is important to consider the type of steel from which the knife is made. As a rule, soft and hard grades are used. Soft varieties of steel are easy to process, but do not hold sharpening for a long time. Hard grades have exactly the opposite properties: they are not so easily sharpened, but they remain sharp for quite a long time.

Most hunting knives are made from hard steels with a high carbon content. The greater the percentage of the latter in the composition, the harder the steel.

To give steel the properties necessary for a hunting knife, alloying varieties with chromium, molybdenum and other inclusions are used. Such metals give the blade corrosion resistance, wear resistance and the necessary margin of safety.

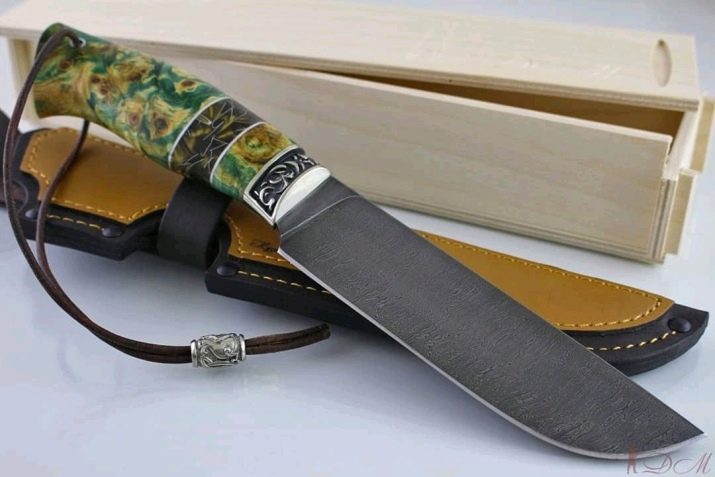

Damask steel is a cast high-strength steel with durability, high strength and a heterogeneous composition, reminiscent of high-carbon steels. The damask variety differs from the ordinary one in its outstanding characteristics: patterns appear on the surface. The darker the background and the lighter the lines of the picture, the more expensive the blade.

Damascus steel is high-carbon and stainless. It depends on whether dopant impurities are present in it or not and in what quantity. If there is a large amount of chromium in the alloy, damask steel is called stainless steel. Good for sharpening. Damask steel is sharpened exclusively with an abrasive moistened with water, changing the grain size from coarse to smaller. The steel is very hard, so the process will take a long time.

Damascus steel deserves special attention. A blade made of this type of material is a multi-layered alloy of soft and hard steel. Damascus is forged from thin plates of metal of different characteristics. This is what gives Damascus steel its properties and contributes to the manifestation of patterns.

It is not recommended to wash the knife with chemical detergents to avoid a chemical reaction. Damascus does not resist corrosion well, so it is important to wipe dry with a rag after use. For long-term storage, it is advisable to lubricate the blade with oil.

Such a blade is sharpened exclusively by hand and, most importantly, smooth movements along the abrasive, and not across. This is the only way to avoid bending the steel layers on top of each other. The sharpening angle of Damascus steel is 45 degrees.

How to sharpen a knife correctly?

Before starting the process, study the sharp tool: what material it is made of and how it is sharpened. The way the blade is processed depends on this. Typically, hunting knives have a sharpening angle of 15 to 30 degrees. Consider the methods of sharpening on a universal knife of double-sided sharpening with a cutting edge angle of 20 degrees.

At home, this process usually does not require special tools, fixtures and devices. Most often sharpening is done abrasive stone with a fine-grained or medium-grained surface. The abrasive bar should be long and wide. There is a high probability that there is one in every kitchen, but if it is not there, then you can purchase one at the hardware or tool store.

abrasive

With this method of sharpening, you need:

- place an abrasive with a medium-grained surface on a table or other flat surface, rest it or fix it, if possible;

- moisten the bar with vegetable oil;

- holding the blade with both hands, draw it along the bar at the required angle several times in one direction, and then the same number of times in the opposite direction (to avoid uneven processing);

- repeat movements and control the state of the cutting edge: in its place, an even strip should form, equal on both sides;

- replace the bar with an abrasive with a fine-grained surface (lubrication is not required);

- with movements without pressure, draw several times along the bar;

- final finishing can be done on the reverse side of a taut leather belt, making up to a dozen movements on each side (to achieve maximum sharpness);

- check the knife for sharpness.

Mechanical sharpener

Mechanical sharpeners are sold in many hardware stores and well-known retail chains. Such a sharpener does not take up much space and does not require special skills. It is a body with sharpening abrasives located inside at the right angle. The case has slots through which the blade will contact the whetstone.

The sharpening process is not difficult: the blade is inserted into the slot, several translational movements are made. The knife is then checked for sharpness.. This method will help to quickly maintain the condition of the knife in an acceptable condition, but it cannot be compared with manual sharpening in efficiency.

Such tools are presented in a wide range and have different prices. A sharpener with high-quality abrasive, convenient device and compact size will not take up much space and save time. You can also find pocket sharpeners for camping use or electric options for sale, but they will cost a little more.

Musat

The device is a steel or ceramic rod with a comfortable handle, reminiscent of a file. Musat is used not for sharpening, but for straightening and finishing blades (translational movements). Musat will fit in a kitchen drawer, but it is not recommended to store it together with knives.

Mode of application:

- the musat rests vertically on a table or board, the required angle of inclination is selected;

- the blade is set perpendicular to the musat;

- movements are made exclusively from top to bottom in this way: the bases of the musat and the knife are in contact at the top, and the end of the musat and the tip of the cutting edge of the blade should touch at the bottom;

- then the sharpening side changes.

It is important to prevent the blade from slipping and hitting the abutting surface so as not to dull the knife even more. Without some experience, it will be difficult to achieve the ideal sharpness of the blade. If such editing does not bring the desired result, you should sharpen the blade manually.

improvised means

There are other ways to sharpen blades. Some of them can be useful not only at home, but also in extreme conditions (hiking, hunting / fishing or a banal outing into nature):

- a leather belt is clamped with feet, a blade is drawn along the reverse side;

- sharpening on a stone that can pass for an abrasive;

- you can sharpen it by sharpening one blade on the other;

- you can sharpen the knife on the rough surface of glass or ceramics.

Results

There are many ways to sharpen a hunting knife at home: with a sharpener, machine, musat. But the most effective is manual processing with an abrasive (grindstone). In the process of manual sharpening, you can control the sharpness of each section of the blade and achieve a sharpening comparable to a razor. This will bring the quality of sharpening to a professional one.

And also the knife requires some care. Prevention is the key to a long service life and serviceability of an expensive product.

For information on how to sharpen a hunting knife, see the following video.