What is the best steel for a hunting knife?

The first and most important requirement for hunting knives is high-quality knife steel. A high-quality knife is easy to sharpen, it does not dull for a long time in the process of work, and will last for many years. A hunting knife should cut, chop and stab well.

Sign of good steel

Steel grades differ in the percentage of carbon in them. It is important to maintain the optimal balance so that the knife is not only hard, but also durable.

If in the process of steelmaking in the alloy there is more than 2.14% carbon in the alloy, then this is, in fact, cast iron - it quickly rusts and is very brittle, which makes it unsuitable for solving the tasks assigned to a knife as a tool.

Alloy hardness

The hardness of steel is calculated in Rockwell units - HRC. It is determined by the percentage of coal in the steel alloy. With a high number of these units, the knife will retain sharpening for a long time. However, with careless or inept movements, it will not be difficult to break it, and it is not easy to sharpen it - not every grindstone is suitable for this. The difficulty of sharpening limits the use of a knife on a hike. Here, steel with a hardness of 55-60 HRC has proven itself well: the canvas smelted from it cuts decently, but is useless in cutting or sawing.

Steel with a hardness of more than 60 units cuts any tree or bone, and simply breaks when bent.

Blade strength

Choosing a durable knife, you will inevitably save on its hardness - these two parameters are mutually exclusive. The higher the hardness, the lower the strength. This is the essence of the difficult choice of the optimal steel for hunting knives. A durable knife, on the contrary, is elastic in itself - even with significant bending, it will not crack.

ancient steel grades

Damascus steel has a hardness of 60 units. It is afraid of moisture and quickly rusts, needs a thin layer of gun oil. The recipe for brewing ancient Damascus steel has been lost, and its modern technology has gone far beyond what was previously used.

Bulat today is one of the rare steel grades. The exact recipe for cooking damask steel has also not been preserved. They tried to recreate it, but they only managed to get closer to the original, but not repeat it exactly.

Damascus steel does not require frequent sharpening, it is resistant to blunting. Perfect replacement for Damascus steel.

Modern views

Russian tool steel - U-8/9/10, Kh12MF. The latter has a hardness of up to 65 units. In steel grade XB5, the hardness index reaches 70, it is also distinguished by remarkable strength.

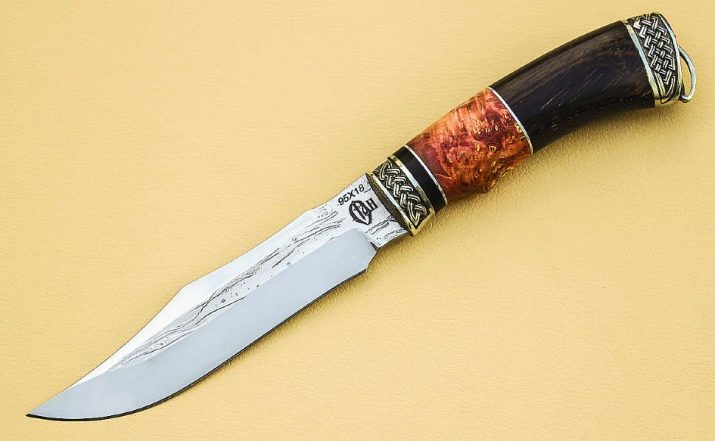

For foreign analogues, the marking is slightly different. These are stamps AUS-6/8/10, in terms of parameters very close to Russian steel grades 440-A / B / C. P6M5K5 - high speed steel, from which drills for metal are also made; to reduce its brittleness, secondary hardening is used. Steel M-2 suitable for extremely high temperatures. But steel 95x18 - a typical "stainless steel".

So, the Americans have their own steel grade 155CM. The Japanese also did not stand aside ATS-35. These two brands are perfect for the product.

Stainless steel 110Х18МШД has a hardness of 60 units. Analogue - German alloy X105CrMo17 / 1.4125, American 440C and Japanese SUS440C.

In any case, the grade of steel from which the blade is made must be indicated on the branded knife.

Steel grades X12VM, 40X12, 50X13, 95X13, 95X19, 65X13, 50X14MF also allow you to make a knife of decent quality.

S35V steel is produced using powder technology and contains an increased amount of carbon - 1.45%. This composition also contains 14% chromium, 4% vanadium, a small amount of niobium and 2% molybdenum. The content of an increased amount of vanadium carbide causes increased hardness (60 units), strength and toughness of this alloy. Does not rust.

VG-10 contains cobalt-based impurities. This steel grade is also used for the manufacture of high-speed conical drills. The hardness of this alloy is 62 units.

Steel grade Sandvik made in Sweden, very hard to harden. In addition to a hardness of 59 units, it has considerable flexibility and holds sharpening well.

Rust resistance

Rust on a hunting knife is formed by contact with blood and water, not removed from the blade in time. It is important to choose an alloy that is resistant to rust - ideally, completely stainless.

Additional knife blade coating

To improve the characteristics of steel, alloying components are added to it: manganese, chromium, nickel, vanadium, molybdenum, silicon, tungsten and others. For example, manganese and silicon make it possible to forge a knife. Tungsten, chromium and nickel prevent steel from rusting quickly.

The knives are the best coated with titanium or cobalt. The hardness of such a blade reaches 90 units, which allows it not to lose factory sharpening for a long time, without losing strength, but it also costs a lot of money. Titanium or cobalt coating is easily recognizable by its brownish golden hue.

On practice

Real practical tasks in field conditions are skinning the carcass of a dead animal, cutting products, cutting tree branches, protection from predators. In third place after durability and rust protection is the ease of use of the knife. With each use, the knife is subjected to strong shock loads that only the original product can handle. You will not find the perfect knife, and there is always the opportunity to choose the best product available. Some knives break when thrown and from careless handling.

The knife is not an ax or a dart: it primarily cuts well, and does not chop or pierce.

A high-quality knife, with a light blow to the working blade, makes a distinct and clear metallic sound, which indicates the integrity of the alloy, the absence of microcracks in the blade.

Famous brands

When presenting a hunting knife as a gift to a friend or acquaintance who is actively interested in outdoor activities, pay attention to well-known brands of knives. The best in execution and quality knives are produced by the German firm "Solingen", the Swiss "Wenger", the English "Winkison". The Germans are in the lead here, their products are of the highest quality, but the price is not cheap either. They are followed by Sweden and Finland in terms of the quality of knives, producing knives from Elmax steel.

Japan, the USA and Finland are countries where hunting as an occupation and as a hobby does not lose its popularity. They are responsible for the manufacture of hunting knives, optimally combining centuries-old traditions and modern technologies.

In Russia, Kizlyar and Zlatoust knives are extremely in demand - their quality is not inferior to American or Japanese counterparts.

Overview of Russian products

"Tourist" has an underestimated butt line, ideal for butchering the carcasses of dead animals or cooking in the parking lot. The knife is perfectly proportioned to the length of a man's hand, it is very convenient to use. It has a non-slip, comfortable handle and comes with a sheath.

"Wolf" somewhat thicker and has a slight bevel that makes it easier to cut the fishing line or net. Complete with African wood handle and leather sheath.

"Dace" more versatile, suitable for fine cutting and chopping. Its sharply sharpened end easily pierces the skin of an animal. The handle is made of three high quality materials.

"Combat-2" narrower and longer, good at separating meat from bones and cutting food before cooking.

"Mole" has a natural pattern on its blade, reminiscent of an oil film on water. The average length of the blade cuts well and pierces the material being processed.

All these knives are sharpened with a fine-grained whetstone, which allows the precise blade to retain its sharpness for a long time. Such products have a very good rating in the overall standings of high-quality highly specialized knives.

If hunting for animals or making a wooden shelter from the weather is not your plan, then there is no need to take an expensive knife from leading manufacturers, which is of exceptional quality.

For information on what steel a hunting knife is best suited for, see the following video.