Hunting knives: description, types and selection

Hunters need different weapons and equipment. Of these, it is recommended to pay special attention to special knives. This inventory is no less important for normal hunting.

Peculiarities

A hunting knife is required to:

- cut up the booty;

- prepare stakes for traps;

- cut small branches for firewood;

- finish off the wounded animals;

- defend against attack.

Choosing a knife for a hunter, focusing only on how it looks, is frankly unreasonable. Experienced miners pay maximum attention to the selection of blades and their sharpening. No wonder such topics are most often featured on hunting forums. But the tool itself appeared much earlier than the forums themselves. It would be true to assume that already primitive hunters needed a field cutter no less than modern people.

Then the knives were made of stone. Their design was very primitive, but in terms of their characteristics, these products turned out to be pretty good. The same can be said about wooden and bone knives.

But then there was no clear division, as it is now. The same tool was actively used in everyday life, hunting, in military affairs, for ritual purposes.

As a result of progressive development, it was possible to create knives that:

- compact;

- well tolerated;

- can be applied in various situations.

Even when fully equipped and equipped, the knife does not hamper the movement of a person. This is true for both ancient and modern practice. Gradually, when developed metalworking appeared, knives began to be used as gifts and collectibles. But on the hunt there are a variety of cases - and therefore many specific options have appeared. Let's analyze them sequentially.

Varieties

A conversation about the types of hunting knives and the features of their device can be carried on for a long time.

Design and shape

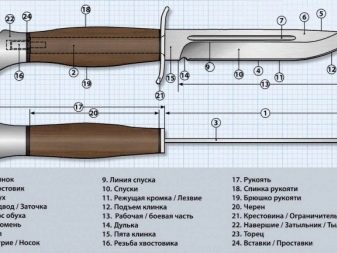

It is immediately worth considering that individual parts of the structure can have a variety of names. The fact is that they even come from different languages. Therefore, it is appropriate to dwell on the most common terms that are often mentioned both in speech and in technical literature (documentation). A steel blank, even for the smallest knife, contains more than just a blade.

Be sure to also use the shank. Its geometry is determined by how the handle is attached to the steel strip. The blade itself usually consists of the same type of parts. The surface of the thickest segment is called a plane or holomen.

Important: in some cases, the word "plane" refers immediately to the entire surface.

The blade refers to the working edges that are sharpened. For any knife, whether it is a simple model, folding or with a saw, the blade passes between the tip and the heel of the blade. Rarely there are other solutions. But we must remember that in some classifications the blade refers to the entire working share of the blade. The knives also have two supplies: this is the name given to the pair of the narrowest surfaces that directly form the edge.The leads serve primarily to slide the sharpening tools.

The heel, also known as the heel, is a segment of the plane that cannot be sharpened and continues the blade. The role of such an element is twofold: increased rigidity, on the one hand, and elimination of interference with blade sharpening, on the other hand. It is customary to call the butt the edge of the blade opposite to the blade. The shape of the butt can vary greatly; sometimes auxiliary functional details are placed there.

The bevel can represent a bend or an inclined part of the butt. Usually it is sharpened so that the functionality is greater. But when sharpening is done in a decorative way, the bevel is renamed into a false blade. On the butts, a section near the handle for the thumb (the so-called) emphasis is allocated. Separate designs with a long handle are distinguished by the fact that the emphasis is transferred to it.

Additionally, allocate:

- points;

- descents;

- ribs;

- valleys;

- factory marking.

A carving hunting knife may well be cast or forged, but in any case, the maximum thickness of the butt is 0.0024 m. If a non-removable stop for the opening finger is provided on folding structures, the blade should occupy the entire space between the tip and the stop. In the general case, the blade is taken equal to the distance between the tip and the limiter. When there is no limiter, the front end of the sleeve or the handle handle is considered the end.

Guard knives are distinguished by the fact that they allow:

- protect the hand during daily work or when striking;

- block the weapons of the attackers (even a saber or something equally serious);

- pull the knife out of the wound as quickly as possible.

It is not surprising, therefore, the position of the legislators, who attributed the guard to the true signs of edged weapons.It is considered to be such a sign if the blade is thicker than 0.0025 m and shorter than 0.09 m.

It is necessary to pay attention to the device of the knife handle. There are 2 key options: invoice (aka lamellar) and mounted schemes. The classic rider design means literally inserting the shank into the handle. Sometimes a cross-cutting approach is used. Then the shank is equipped with a thread. Then a nut with a special decorative configuration is used to tighten parts of the handle. Both solutions apply additional reinforcement with glue or resin.

It is customary to call the section of the handle covered by the palm of the hand.

The name of the back is given to the top of the handle, on which the palm is placed. A traditional solution that has been used for a very long time is the shape of a small barrel. Fingers are placed on the abdomen (that is, on the bottom of the handle). The geometry of the abdomen can vary greatly. It is calculated for various grips, dictated by the scope or tasks to be solved.

An almost indispensable component of the handle of a hunting knife is the subfinger notch. The hollow for the index finger allows you to increase the emphasis during stabbing. There are 2 types of recesses: in the handle itself and on the heel of the blade. Due to the highly smoothed geometry of the handles, it is difficult in some cases to accurately locate the subdigital radii.

The butt is called the back section of the handle, which helps to hold the knife in the hand when removing it from the cuts.

A clip, also known as a binding, is a relatively narrow spacer from the shank to the guard and from the shank to the back. The role of the clip is to absorb energy and wrap around. Thanks to this element, it is possible to prevent the splitting of the handle upon impact. It also helps to make the design more elegant and mitigate the effects of swelling or drying out of the cutting.Rivets, they are rivets - help to strengthen the false handle.

In addition to the listed parts, hunting knives may have some other special parts.

materials

When selecting knives for hunting, it is necessary to take into account not only their geometry, but also the main structural materials. It is very difficult to give preference to one or another substance. So, when evaluating alloys for a blade, you can focus on:

- cutting ability;

- resistance to corrosion processes;

- excellent hardness;

- design flexibility.

These parameters are contradictory: the improvement of one of them is accompanied by the deterioration of other properties. Such characteristics are influenced by the specific steel grades, processing methods and chemical composition. Heat treatment is also very important. In most cases, to obtain all-metal or partially metal knives, they use:

- tool steels;

- steel with alloying additives;

- first-class structural grade carbon steels.

The best alloys are those where the share of carbon is 0.4-1.5%. In terms of cutting properties, steels with a carbon concentration of 0.9-1.2% are in the first place. Russian GOST marks carbon steel of the mass category with a combination of the letters Art. After that, they immediately write the conditional digital designation of the group. If the blade is made of first-class carbon metal, then two numbers are written, reflecting the average carbon concentration (converted to hundredths of a percent).

Marking can also indicate the presence of various alloying additives, their total concentration. Some people highly value HVG or 9HVG steels. They sharpen without problems and form a strong edge. Due to poor corrosion resistance, this metal should be chrome-plated or blued. Blades made of 5HNM steel are also often recommended.

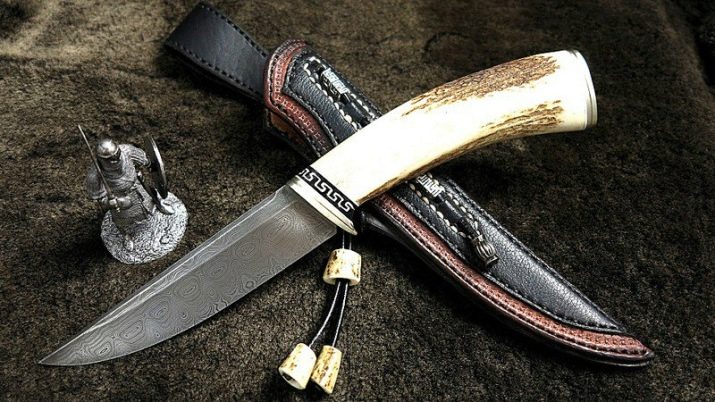

It is perfect for survival in an extreme situation. Even with limited care, the blade will work perfectly, no matter the situation. Sometimes the blades are made of Damascus steel, but this is a very expensive solution. An equally important point is the material from which the handle is made. Even if the blade is good, but the handle fails, users are unlikely to like the knife.

Important: Some materials may absorb odors.

A classic solution is a wooden handle. This product is natural and completely safe. However, you need to make sure that strong and stable wood is used. A soft handle is acceptable only for a mushroom knife, and for hunting and tourism, stronger products are needed.

Popular breeds are:

- boxwood;

- nut;

- beech;

- ash;

- Karelian birch;

- rosewood;

- cherry;

- maple;

- oak.

But even the best wood is far inferior to the latest generation of synthetic substances. It definitely requires care and careful handling. At the same time, connoisseurs appreciate wooden handles for their reliable grip with the palms and the convenience of working in the cold. Quite popular handles made of typesetting birch bark. For their manufacture, only the upper part of the birch bark is used, which is pressed into briquettes and glued in layers with epoxy resins.

Birch tar repels water and eliminates rotting. In addition, this substance almost does not conduct heat. It is comfortable to hold on to, regardless of the weather. However, the bark absorbs all odors too easily. Therefore, fishermen and hunters need to think three times before buying such a product.

Care is reduced to washing, drying, followed by the application of natural wax or linseed oil.Hydrogen peroxide is used to eliminate blood stains. The method of production of handles from type-setting leather is approximately the same as from birch bark. The disadvantages and advantages of these materials are similar. But the skin is even more active than birch bark, absorbs water.

With errors in the operation and storage of the knife, you may encounter rotting of this material. Therefore, such products are suitable mainly for suburban short-term hunting.

If you plan to go into the forest for several days or very often go for prey, you should look for something more impressive. The more popular solution is textolite, which does not absorb excess odors and water, is not impregnated with fats. Textolite handle will not slip out of the palms.

Still such a handle will not dry out or swell. The problem can be a frankly inexpensive look. But it is characteristic mainly of "simple" models. Choosing a knife from a major manufacturer, there is no doubt that the handle will look attractive. After all, there are methods that allow you to form an interesting ornament on the textolite.

Organic glass is also highly resistant to grease, moisture and dirt. Plexiglas does not retain odors. He is also able to transfer a significant mechanical load. You can be afraid of scratches and chips. However, these defects can be easily removed by polishing. From organic glass, painted in different colors, even many handles of gift and collection knives are made. Some of them are marked with the symbols of special forces units.

Kraton handles definitely deserve attention. This synthetic substance at the same time:

- mechanically strong;

- perfectly grips with the hand;

- nice when working in the cold.

Such solutions are in demand in tactical and survival models. They are actively used by many foreign manufacturers. Some companies are trying to use combined designs. The possibility of combining different materials is determined solely by the imagination of the developers. Technologically, all such solutions are very simple. Returning to Damascus steels, it is worth emphasizing that they are still used in carving knives. Examples:

- "Lynx-2";

- "Uzbek" (with a handle made of Karelian birch);

- "Pheasant";

- "Cleaver".

Top Models

And yet it is worth concluding that there is no universal knife for hunting. It's not just that some materials are preferred by some, while other hunters have a different opinion. The functions of the cutters themselves are so diverse that one has to think about purchasing a whole set of products for different tasks. In this case, it is useful to see which options are considered the best and can be used in most cases.

Hunt

The rating will definitely include knives from the Hunt collection, released by Benchmade. This line can hardly be called new, since it has been produced since 2014. However, this is rather a plus, because a lot of people have already met with such products, and you can easily find reviews. Knives of this series are both specialized devices for professional hunters and mass field products. The main properties are:

- total length 0.16 m;

- blade 0.068 m;

- handle 0.092 m;

- weight 0.1 kg;

- development and production - USA.

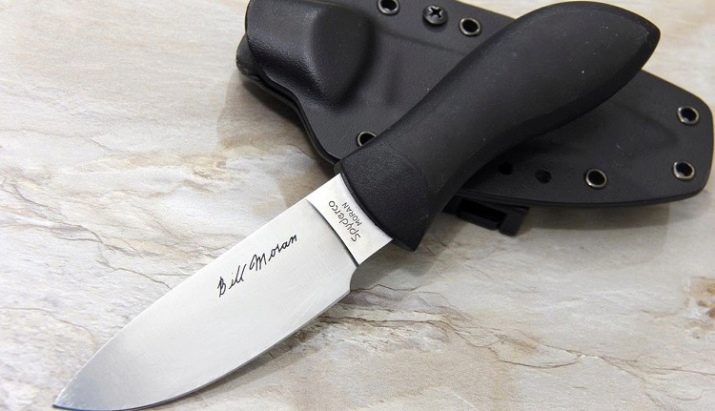

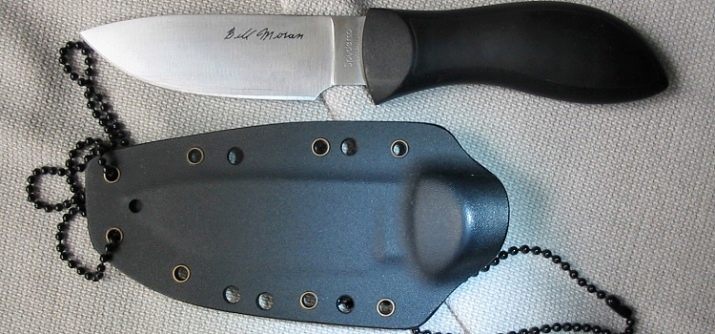

Morana

Although not the most beautiful, but almost legendary is another American knife - the so-called Moran knife. It is manufactured by only one company, Spyderco, and no other organization in the world has the right to do so legally.The size of the products is relatively small, and the blade is rigidly fixed. The main parameters are as follows:

- total length 0.205 m;

- blade length 0.099 m;

- steel grade VG-10;

- knife weight 0.084 kg.

Important: real Moran knives, which were the fruit of the handiwork of the master himself, are almost impossible to find on sale. If they are, then only at a price comparable to the payment for a solid car.

But the serially produced modification is very good. The guarantee for this is at least impressive manufacturer reputation. The kraton handle is perfectly held in the hand, even if covered with blood and moisture.

Users note the even assembly of the scabbard and the presence of a hole for the outflow of water. Despite the shallow insertion of the knife, its hold is tight. Thanks to the special thumb rest area, you can pull the tool out slowly and silently. This is important when sneaking up on animals. The blade is polished in production to a mirror state. You can cut the meat very easily, without any tension. The knife will cut through the thickest parts of the carcass and easily penetrate inside. Straightening the cutting edge is easy.

Important: from the subfinger notch, the finger can slip onto the blade. You need to keep it there carefully and only carefully looking after your hands.

Mora

In the review, it would be foolish not to mention the knives of the Scandinavian format, produced under the Mora brand. The range of this brand includes offers for tourists, for home cooking and for artisans. Best for hunters bushcraft forest modification. Swedish developers have tried to ensure that the sharpness remains unchanged and to eliminate rust. The parameters of this model are as follows:

- total length 0.274 m;

- blade length 0.109 m;

- handle length 0.165 m;

- total weight 0.142 kg.

It is worth noting that the appearance can give the impression of some kind of rough cheapness. But this feeling immediately disappears when the use of the knife begins. Only high-tech, reliable materials are used in its design. Scandinavian Sandvik steel contains 13.5% chromium. Exceptional Rockwell hardness is obtained by quenching with liquid nitrogen.

"Wolf"

Among the knives made in Russia, the "Wolf" deserves attention. This version is not a melee weapon, and therefore you can carry, carry, sell and buy it absolutely calmly. Used to make the blade high quality stainless steel grade 95X18. The manufacturer guarantees excellent cutting performance and a rational ratio of cost to quality. Products are certified in the Russian Federation. The key parameters are:

- total length 0.285 m;

- blade length 0.159 m;

- Leather Case;

- total weight 0.147 kg;

- combined type handle (made of walnut, birch bark and brass).

Buck 110BRS

Of the folding models, it is appropriate to pay attention to the Buck 110BRS. This version has been mass-produced since 1962, which already speaks of its high quality. For all the time of use, the knife has proved to be as reliable as its monolithic counterparts. The ebony handle with copper inserts looks very attractive. The company gives a lifetime warranty, but it is worth noting that the blade is not too long, and the prefabricated structure is inferior to monolithic blocks.

When choosing a folding knife with a saw, it is appropriate to pay attention to the aircraft model. This design has been produced for over 40 years and has repeatedly rescued pilots after emergency landings.Despite the slightly archaic appearance, the product is very reliable. As for the profile, the best choice for versatility will be models with a straight butt. The Bowie knife format is also quite popular.

How to choose?

The choice of a hunting knife categorically cannot be reduced only to determining the appropriate brand and model. It is more correct for novice hunters to focus on the objective parameters of products, and not on their abstract reputation.

Important: for all the quality and reliability of army and "special" samples, many of them cannot be operated without special permission. The uncontrolled circulation of such knives is prohibited by law. Speaking about the qualities of a knife that are important for a fisherman, we should immediately mention its mass.

Large and heavy models look impressive and even menacing. But it is better to save them for demonstration purposes or for cutting meat in a kitchen. And when hiking through difficult terrain, even “only a dozen grams” matters. When hunting, careful handling is very important. Otherwise, it will be impossible to remove the same skins without deformation.

Important: because of the same reason, you should refuse to purchase narrow knives with a long blade.

Buying a machete makes sense only as an addition to the main working tool. Another important rule is rejection of serrated blades. Such sharpening is simply unacceptable for hunting, because it does not allow you to make an accurate, elegant cut. At the same time, this method of sharpening does not provide the necessary sawing properties. The rational sharpening angle is not lower than 30 and not more than 45 degrees. With this approach, it will last longer. Experts also point out that the handle is desirable to choose from natural materials. If it is not birch bark, then at least it is hornbeam or beech.Such structures do not slip.

But alder wood and genuine leather, on the contrary, will slide more strongly after contact with water. Plastic is considered neutral, and metal should be categorically discarded. It is impossible to work with him in the cold without gloves.

It is often mentioned that the best scabbards are those that are made by oneself. But such an opinion has no real basis.

It is almost impossible to make high-quality scabbards in artisanal conditions. And from factory samples, it is worth highlighting those that are equipped with straps or valves. This reduces the risk of tool loss. As for the steel in the blade, Damascus is not very good. Rather, the overpayment for it does not pay off with real benefits.

The best steel, according to professionals, is stainless grades with a hardness of 55 HRC. It makes no sense to take a simple stainless metal of low strength. It does not last long and sharpens very badly. For your information: 95X18 steel is also quite badly sharpened. But this is to some extent justified by high stamina.

According to professionals, the best choice for a hunting knife would be steel 50X14MF. As for the preference for fixed or folding options, there is not much difference. You can safely rely on personal tastes. Of the blade profiles for hunting use, drop point, clip point are best suited. Such solutions are ideal for the main part of the manipulations performed.

And one more nuance that is often forgotten is a purely individual fit of the knife.. Other items seem to be quite consistent with the requirements, but it’s not convenient to put them in your hand. Then it is better to refuse the purchase altogether.It is advisable not only to “hold the knife in your hand”, but also to check it on the backswing, on a conditional blow. For this reason, it is not advisable to buy such items online.

How to sharpen?

The need to do this sooner or later arises for any hunters. Moreover, it can be expected that such a need will appear quite early. After all, the knife is used for hunting very intensively. Having acquired such a tool, it is important to see what sharpening angle is set at the factory or in the workshop. Violating this angle, you can only worsen the quality of the cutting edges.

A knife intended for deboning meat and its primary cutting is sharpened by 30 degrees. At an angle of 20 degrees, you will have to sharpen universal products. But the tool for especially fine work needs to be sharpened at an angle of 15 degrees.

Important: it is worth focusing on the instructions of the knife manufacturer. Its engineers know exactly which option is ideal.

In any case, the sharpening angle should be the same for both sides. As for the sharpening tool, it is better to purchase a special tool at the same time as buying a knife. If it is bought later, it is necessary to give preference to products of the same brand. In the field, portable mechanical sharpeners are ideal. A few simple movements are enough to restore the device to its condition again.

At home, it is advisable to use an abrasive stone. Among the various options, it is necessary to select wide and ideally flat ones no longer than 0.25 m. And also a mandatory requirement for a good stone will be the density of the structure, consisting of medium or small grains. It is necessary to work only on extremely flat surfaces. It is highly desirable to fix the grinder.The blade is held with two hands, and then, under pressure, it is pulled crosswise from each side.

Sharpening is stopped when the cutting edge is covered with a shiny stripe. The size of this strip on one side and the other should be the same. Next, change the whetstone to the same, but with a finer grain. Now you can fine-tune the sharpness. A well-sharpened knife will cut through a sheet of newspaper placed vertically in one easy movement.

How to choose a hunting knife, see the following video.