How to make a floor for a tent

A good, solid tent is of great importance both for recreation and for professional use. Therefore, its choice must be approached very carefully, without saving time and money. But no matter how high-quality the tent is, after a while it will begin to deteriorate.

First of all, the bottom begins to wear out. This is explained by the fact that the underfoot coating is easily damaged when walking, bumping into stones or branches, the material is rubbed and destroyed. A special blow is taken by the floors in the tent during turbulent weather conditions. In the cold season, the base becomes the key to keeping warm in this small room.

A separate floor for a tent, or as it is often called, is not so easy to purchase a footprint. The fact is that many manufacturers do not make additional floors at all. Others, realizing the benefits of this product, sell it for a rather large amount. Objectively speaking, most often an additional bottom is not worth the money, so a better option arises - do it yourself.

Flooring manufacturing

In fact, making a floor for a tent is not such a difficult thing. Even those who have never made anything like this can do it.Here it is very important to accurately measure the necessary parameters of the product, so a tape measure or centimeter tape must be in the workplace. In addition to it, scissors and a sewing machine are needed. If there is no sewing machine, then you can sew the product by hand, but this will take much more time and, most likely, will not be so neat.

And, of course, the materials themselves for the insulated floor are needed. We will consider the difference in materials later, while we study the basic manufacturing instructions.

First of all, you should measure the tent, which is disassembled. It depends on the accuracy of the measurement whether the floor will let the wind through and whether it will remain protected during rain. The presence of the old floor from the tent simplifies the situation, then all calculations should be done on it - it will take less time, and it will be easier to do it.

One of the possible materials is an awning. It is easy to find in the store, you just need to choose the necessary moisture resistance. Next, a heater is needed, one of the possible is isolon. For convenience, you need zippers, as long as possible, it is better if with protection from moisture. Zippers can be purchased at any fabric store.

It is not recommended to sew the floor for the tent in one layer, since when folded it will take up a lot of space, which is extremely inconvenient. Therefore, the isolon must be divided into blocks, each of which should be sheathed with an awning. What size of blocks to take, you should choose yourself. The easiest way is to fold the isolon into several parts, and cut along the lines formed. Thicker material that is difficult to bend you will have to delimit visually, and cut along presumably correct lines.

It is important to think over all the details: holes for the holes and the presence of a zipper in each block with insulation.This option is optimal, it will allow you to easily remove the contents of the floor and dry. The outer contour of the product should be tucked. It would be appropriate to reinforce the edges with fabric straps.

The final step in the manufacture of the floor for the tent is the careful stitching of all the necessary lines. Now the product is ready.

The difference between winter and summer options

Winter and summer tents are quite different. The summer tent is made of lightweight material:

- interior – has the appearance of a grid to ensure good ventilation;

- outer layer protects from light rain and wind.

Winter ones have a “winter skirt” in their mandatory arsenal, which must reliably protect against snow getting into the tent. In addition, the winter tent has a greater number of strong poles to withstand strong gusts of wind.

It is easy to guess that the functions of the floor for different types of tents will be different.

For a summer tent, it is preferable to take the material without insulation; in this case, an ordinary awning or banner floor is perfect. Its ease of manufacture lies in the fact that no need to sew in insulation, you just need to measure the parameters correctly, and easily make the floor.

The winter floor in the tent should be warm. This function is taken over by insulating materials. Making a floor for a winter tent will be more difficult than for a summer one.

Materials used

The variety of materials in this case is not too wide, but it is quite enough to choose a product with the most suitable characteristics.

Are popular foam floors. Penoplex is obtained by adding catalyst gases to polystyrene. With such a connection, a dense matter with pores is formed.Externally, the material is very similar to polystyrene, but unlike it, it has high strength.

The positive characteristics of this material are enough:

- excellent thermal insulation;

- moisture resistance;

- soundproofing;

- durability.

There is also a minus. The fact is that this product contains a minimum amount of styrene, which, even in small quantities, is harmful to the human body.

There are several varieties penoplex, they differ in the density of the material.

Also enjoys well-deserved popularity isolon. Isolon insulation has almost the same advantages:

- durable material with high density;

- has excellent sound insulation;

- excellent heat retention.

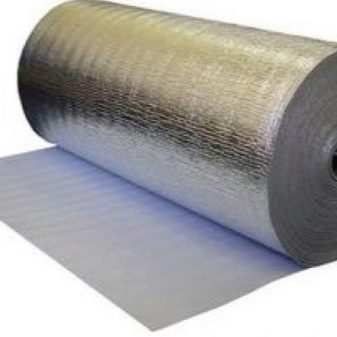

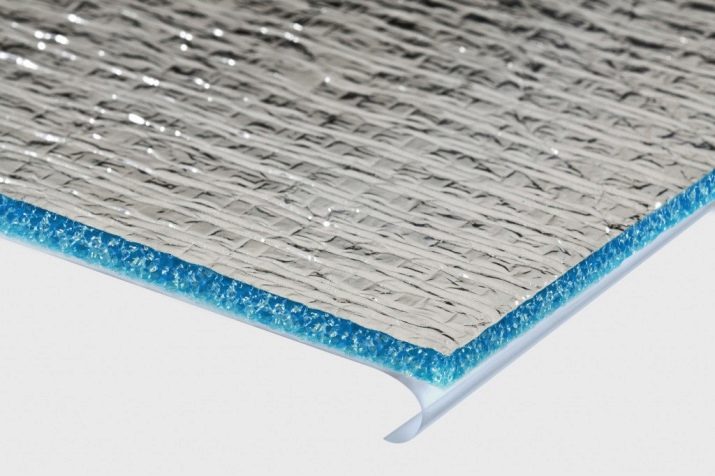

Slightly inferior to isolon material such as penofol, which is made from polyethylene, foaming it. Usually the material is covered with foil on one or both sides, the foil is necessary to enhance the positive functions of the material.

Another interesting material is splenitis. It consists of polyethylene foam and has a sticky layer. This is convenient if the block of material needs to be fixed securely. Using this insulation in the manufacture of the floor for the tent, you can not flash it as carefully as those materials that are not fixed.

Additional bottom

Sometimes one floor is still not enough, in which case an additional warm bottom will be needed. Let's figure out how to make it.

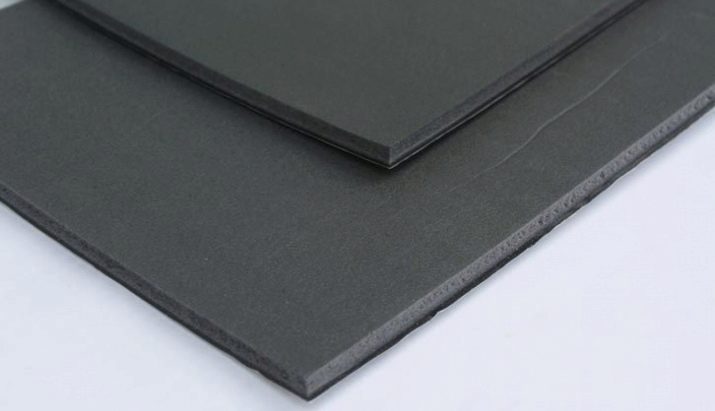

An additional warm bottom is easier to make with your own hands than the entire floor for a tent. An excellent solution would be to manufacture from EVA material or from a banner. The substrate can be made of any insulation that is most suitable for a particular case.

EVA and banner materials are durable and elastic, have excellent heat-insulating characteristics, durable, withstand a wide temperature range.

In order to prepare an additional bottom for the tent, it is necessary to accurately measure the required size of the product, cut out the selected material and, if necessary, sew in insulation. The product resembles the design and principle of a duvet cover, is made simply, and lasts a long time, reliably providing warmth and comfort.

How to make a floor for a winter tent with your own hands, see the next video.