How to make a folding picnic table with your own hands?

Hiking involves recreation, requiring a large number of specialized items and devices. One of these structures, which you can’t do without in nature, is a camping table. If you have certain skills, it is quite possible to make it with your own hands.

Features and types of structures

Varieties of camping tables differ from each other in a list of various characteristics. Their list includes the following:

- cover material;

- design and material of the supporting part;

- functionality;

- the size.

The range of the modern tourist market offers a wide selection of camping table modifications. Among the list that makes up the main model range, you can find folding tables, detachable, one-piece, combined and others. A folding camping table consists of the main parts: table top, supporting elements, fasteners.

The parameters of these components may vary in shape, size and other design characteristics.

The principle of operation of the folding mechanism of the camp table is similar for all models. The main rules for its implementation are simplicity of functionality and saving free space. Modifications of detachable tables allow you to separate their supporting parts from the tabletop. Depending on the design, the parts can be stored together or separately. Models of one-piece camping tables suggest a partial separation of the supporting part from the tabletop. In this case, the parts that make up the structure are stored together.

Tourist picnic table, can be used in different ways. Depending on the need, it can serve for the processing of various kinds of food. For example, on a camping table, you can butcher meat, prepare food for further cooking procedures (frying, boiling, drying, and so on). Among other things, you can use this table as a storage surface for various camping supplies, such as crockery or other kitchen tools.

If the design and size allow, the table can be installed in a tent, which makes it possible to use it for its intended purpose in adverse weather conditions. In order to meet the individual needs of a particular tourist group, you can assemble a homemade camping table.

To achieve the best assembly result, it is necessary to take into account the full range of needs that may arise on a hike or a picnic.

Materials used

The factors that determine the intended use of a camping table depend on what materials it will be made of. Before choosing a material the degree of expected load that will be exerted on the product during its operation is calculated.

Boards

It is allowed to use boards as the main material that makes up the surface of the countertop.For example, you can use boards taken from a loading pallet. However, they are not the best option. This is due to the technical characteristics of the plank material, which determine how it is attached to the supporting elements.

To attach the table top boards to the top of the table support legs, you must use two fastening points on both edges of each individual board. If bolts are used for attachment, then a minimum of 4 bolts will be required per board, which will increase the amount of consumables used in assembly and increase the weight of the entire structure.

Chipboard

Chipboard as a countertop has characteristics that meet the criteria for greater efficiency. However, its main disadvantage is the susceptibility to structural destruction. Under the influence of moisture or destructive loads exerted on various fastening currents, it quickly collapses, which leads to the appearance of factors of defectiveness of the entire structure, a decrease in the period of uninterrupted operation and a decrease in reliability.

Plastic

Plastics are materials that meet the practicality criteria to a greater extent than other materials. It is not affected by moisture and, depending on the brand, is resistant to most loads. However, finding a suitable plastic blank is extremely difficult.

Plywood

The most advantageous material for the manufacture of countertops is plywood sheet. Its structure suggests the presence of several wood layers interconnected by gluing.At the same time, the direction of the wood fiber of each layer is perpendicular to the others, which has a positive effect on the parameters of rigidity and resistance to deformation loads.

The structural characteristics of plywood make it possible to equip reliable fasteners that serve uninterruptedly for a long time. If there is enough of this material, it is also possible to design a "suitcase" type camping table, which is stored and transported in a closed case. For the manufacture of legs, it is recommended to use a metal square tube with a side size of at least 2.5 cm.

Its profile provides a sufficient level of structural rigidity and makes it resistant to deformation loads.

Required Tools

To make a camping table with your own hands, you need to prepare a set of basic tools with which the assembly will be carried out. In the list of the set, the following names of tools can be noted:

- wood saw or electric jigsaw;

- welding inverter (if possible);

- electric drill or screwdriver;

- angle grinder;

- circular nozzle on the angle grinder for grinding;

- a hammer;

- square;

- brushes or a small roller;

- marking devices (pencil, marker or chalk);

- measuring instruments (tape measure or ruler);

- other related tools.

In the manufacture of metal support legs, it is desirable to use a metal welding machine. This is due to the fact that the welded joints of individual parts of the structure in this case are the most durable. In the absence of a welding inverter, you can use bolted connections. To do this, you need to prepare a certain number of bolts and nuts.The presence or absence of certain items of tools will be determined by the type of design of the future table and the method of its assembly.

Expendable materials:

- sandpaper;

- drill;

- self-tapping screws;

- bolts;

- electrodes;

- cutting wheels on the grinder.

Additional consumables may be required depending on the characteristics of the specific table model.

How to make?

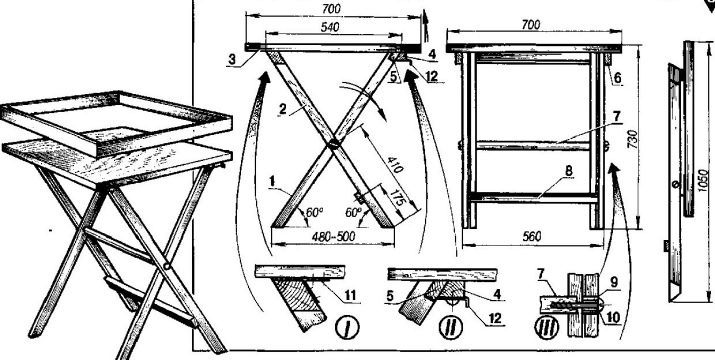

Before starting the manufacture of a homemade camping table, it is necessary to prepare drawings of its design. The drawings should indicate the dimensional parameters of individual parts of the product: table tops, height and width of the supporting elements, data on the dimensions of the workpieces used. Fastener locations should also be marked on the drawing.

Support legs

For the manufacture of support legs, it is necessary to cut off segments from a square metal pipe, which will be the legs and the jumpers connecting them. The optimal height of one pair of legs, taking into account their diagonal arrangement, is 70 cm. The height of the other pair should be 3-5 cm more, which will compensate for the offset that occurs when the 2 reference pairs are cross-connected.

The width of the upper jumpers connecting the legs is equal to the width of the table top, reduced by 20 cm. Reducing the width of the jumper is necessary to free the end edge of the table top from the proximity of metal parts and ensure ease of use. The resulting blanks are welded in the form of the letter "P". U-shaped pairs should be made in such a way that one of them fits into the inner perimeter of the other with a minimum gap.

Through holes are drilled in the side faces of the legs, penetrating both pairs in the same place.Bolts are inserted into these holes, the length of which should allow them to pass through the thickness of two legs and go out on the other side by at least 1.5 cm. The protruding distance is needed to screw the nuts onto it. Washers are laid under the bolt head between the walls of the legs that are in contact with each other and under the nut, which reduces the friction of the workpieces against each other.

It is recommended to use a lock nut whose profile does not allow it to be completely screwed onto the bolt. This will help maintain a sufficient gap between the workpieces, causing their free movement relative to each other. At the same time, a Grover is placed under the nut, preventing its arbitrary unscrewing.

If there is no counter-profile nut, you can rivet the edge of the bolt opposite its head. Violation of the integrity of the extreme threads prevents the screw connection from unraveling. Finished sliding legs are prepared for further installation.

As part of this preparation, it is necessary to clean the welds from scale and clean them with a grinding nozzle installed on the grinder.

Next is the painting of the blanks. Paintwork will protect them from corrosion. During painting, bolted connections can be dismounted. This will help to avoid clogging of the threaded channels and reduce the mobility of parts of the mechanism. In the connecting crossbar of one of the support pairs, 2 holes are drilled at an equal distance from the corners. They are needed to further attach the legs to the bottom of the tabletop.

table top

Made from a single sheet of plywood. The value of its thickness can vary between 1.5-2.5 cm. The optimal length of this blank is 70-75 cm, and the width is 60-70 cm. The final weight of the finished product depends on these values. At a distance of 20-30 cm from the short edge, 2 holes are drilled, the location of which coincides with the location of the holes drilled in the connecting bar.

Furniture bolts with rounded heads are inserted into them. They must pass through the tabletop, the jumper of the support pair and go out on the other side by at least 1.5 cm. On the opposite edge of the tabletop, on its lower side, a longitudinal bar is attached.

The connecting jumper of the second support pair, which is not attached to the table top with bolts, will rest against it. The final step in assembling a homemade table is painting or varnishing its countertops. This will protect it from moisture and other external factors, as well as give it an aesthetically pleasing appearance.

How to make a folding picnic table with your own hands, see the following video.