How to make an anchor for a PVC boat with your own hands?

Regrettably, but at the moment there are no anchors (anchors, holding devices, braking devices) in retail outlets that could fully satisfy the needs of anglers. As a result, every self-respecting fishing enthusiast tries to make a holding device for his own swimming facility with his own hands. Well, we, in turn, will try to help with this.

Requirements for homemade models

For any PVC boat, you can make an anchor suitable for a specific case with your own hands. In order to achieve the desired result in manufacturing, the following requirements must be taken into account.

- Under no circumstances should the device have cutting surfaces or sharp corners. Despite the fact that polyvinyl chloride is much more reliable and stronger than rubber, it is preferable not to put yourself at risk on the water. Careless handling of sharp objects can cause damage to the craft, which in some situations is most often life-threatening.

- The device must be treated with an anti-corrosion agent.

- The sample of the braking device must be selected taking into account the bottom. If there is a possibility of hooks, then he must have the ability to unhook.In this case, either soft paws or a float are used.

- For a PVC boat, it is required to select a small-sized modification, which can be folded. Such a design will create less discomfort for the fisherman in the process of moving the boat.

- The ideal anchor mass is 10% of the ship's carrying capacity. The next parameter that should be used when choosing the right sample is the length of the craft. To calculate the ideal mass of the anchor, the length of the craft, embodied in centimeters, is multiplied by a factor of 0.01. Thus, if the boat is 320 centimeters long, then the mass of the anchor will be 320 × 0.01 = 3.2 kilograms.

- The rope (rope, rope) that is used with the restraint must be made of artificial materials. Since these materials are not subject to decay (as opposed to natural ones) and have a long service life. The length of the rope must have a good margin.

- The presence of a small piece of chain between the anchor and the rope contributes to the most secure holding of the craft.

Tools and materials

Since we will consider the process of manufacturing several varieties of anchors, we will need different materials and tools, respectively.

For an anchor according to the Kurbatov method, you will need:

- steel wire (section from 8 mm);

- 3 mm sheet steel;

- a piece of iron bar, with a circular cross section of at least 12 mm.

To make an anchor cat you will need:

- a strong iron bar with a circular cross section of approximately 30 mm, a length of 20-30 cm;

- a piece of tube slightly larger in diameter than a rod, approximately 2-3 cm long;

- 2 mounting rings;

- 4-6 mm sheet steel.

A lead restraint would require only lead.

For a collapsible holding device, you will need:

- non-corrosive steel tube: 25 mm in diameter, 270 mm in length;

- bushing with 25 mm M12 thread;

- a piece of sheet stainless steel;

- wire with a cross section of 5 mm;

- lead.

For a floating anchor you will need:

- dense, rigid fabric with water-repellent properties (tarpaulin, canvas, etc.);

- rope and special glue.

Manufacturing methods

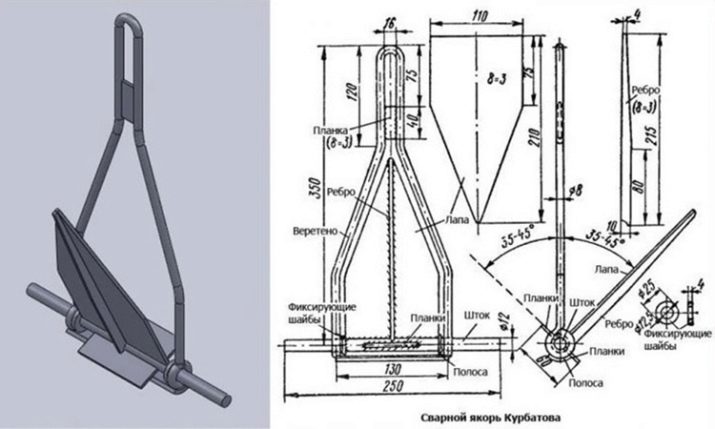

Homemade holding device for a rubber boat, according to the Kurbatov method

The manufacturing process is not particularly complicated. The anchor is a welded structure (drawings of which are presented below), characterized by small dimensions and relatively low weight (approximately 2 kilograms).

This device has only one paw and a forked spindle of medium size. This homemade holding device perfectly holds boats up to 5 meters long.

Now consider a step-by-step manufacturing guide.

- A spindle is bent from the wire, to the upper region of which a bar is fixed by welding.

- Fixing washers and slats are welded to the stem (rod). They are required in order to be able to turn the paw under water so that it grapples with the ground.

- The ends of the spindle are welded at the bar by means of a metal plate, which is required to ensure the working properties of the paw.

As it was written above, the mass of an anchor for a boat made of polyvinyl chloride, assembled according to the Kurbatov method, is approximately 2 kilograms. It perfectly holds the craft on the bottom covered with silt and sand.

Do-it-yourself cat anchor for a PVC boat

We cut from a steel sheet:

- 4 stripes in the form of a rectangle - 2 centimeters in width, 10-15 centimeters in length;

- 4 stripes - 2 centimeters in width, 4-5 centimeters in length, round off the edges;

- 8 stripes - 2 centimeters in width, 3 centimeters in length, round off one edge.

- then we cut out 4 pointed triangles from the same sheet, which will play the role of the paws of the holding device.

We fix the mounting rings to the upper and lower parts of the main pipe by welding.

To the bottom of the pipe we cook 4 three-centimeter strips from 8 prepared ones, having made holes in them with a diameter of 5-7 mm in advance. Horns will be fixed to them. The remaining 4 strips are cooked in the same way to the segment of the 2nd pipe. This pipe must move freely along the main pipe.

In 4 strips 4-5 centimeters long, we make holes of the same diameter at the ends. We drill similar holes from one edge of 4 strips, the length of which is 10-15 centimeters.

From the other edge, the long strips are narrowed, and in this area we fix triangles to them by welding. We make cuts in the middle of these strips, after bending them and welding at the bend. Thanks to this, the horns will acquire an arcuate configuration.

We fix the resulting horns with iron bars to the "ears" located below. We fix the four-centimeter strips in the same way to the “ears” on the second piece of pipe. We put this segment on the main pipe. We drill holes in the horns so that it is possible to connect them with rods with holes on the other edges of the four-centimeter strips.

Folding cat anchor

There is also a folding cat model. It is similar to the device described above, but due to the sliding clutch and the separate swivel of the paws on the bar, it has the ability to fold. When the clutch is at the lowest point, the paws are separated and fixed, and at the highest point they converge.

Often, the paws are fixed to the bar by means of cotter pins made of copper, which, in case of a dangerous hook, makes it possible to save the anchor - the cotter pins are cut off, releasing the holding device.

Lead Anchor for PVC Boat

A particularly straightforward method for making your own inflatable boat restraint is to cast it out of lead. To do this, we take approximately 3-5 kg of lead (based on the dimensions of the ship). While it passes from a solid to a liquid state, it is necessary to make the shape of the future anchor.

Liquid lead is poured into the prepared flask. After it cools down, we pull out the home-made holding device from the impromptu form and clean it from unnecessary metal sagging.

Then we drill a hole in the stem for the rope. To make the anchor drift less, several additional holes can be drilled in the hat itself.

For fishing in stagnant waters, such actions can be omitted.

Create a simple collapsible anchor

So, we have prepared the materials, let's do the assembly. We weld a sleeve on one end of the stainless steel tube.

We make paws from strips of non-corrosive steel with the following dimensions: length - 26 cm, width - 4 cm, thickness - 0.4 cm. The ends of the paws must be treated with sandpaper.

We weld 2 strips on one of the paws in order to prevent the paws from turning when the anchor is assembled. We string the paws on the stem and tighten with an M12 nut. In order for the anchor to be assembled and disassembled without the use of tools, we weld a ring to the nut. At the other end of the anchor, we make a hole, insert another ring into it (diameter - 40 mm, wire section - 5 mm). The mass of this design will be 1.6 kg.

In order to increase the stability of the craft during gusts of wind, you can fill the anchor rod with approximately 2 kilograms of lead.

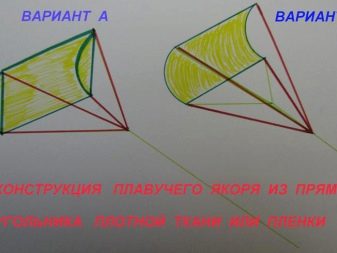

Drogue

The key issue here is to establish all working dimensions. If for traditional devices the main parameter is the mass, which should be equal to 10% of the mass of the floating craft with the maximum load, then in the variant with the floating version, the dimensions of the dome will be the main (inner and outer diameters), the length of the main cable and truss system.

Usually, for sewing, a pattern previously created on paper is used. The pattern spreads on the material, the workpiece is cut out. In a situation where the material is very dense, you can sew a dome from several elements. Then, for each element, it is necessary to leave allowances for seams.

The workpiece is sewn with strong threads - it is more reliable to use synthetics, as it has high weather-resistant properties. Then a hoop is made from a strong material for the base of the holding device. If the configuration is cone-shaped, then a cross is made, to which the edges of the fabric blank are fixed.

Next, slings are sewn, usually there are 4 of them. If in a suspended state the holding device hangs at a right angle to the plumb line, then everything is fine with balancing, if not, then adjust the distance between the lines. At the end, the slings are assembled into a knot and sewn to the main rope.

All seams should be covered with a moisture-proof adhesive, such as sealant.

Helpful Tips

Making your own anchor is easy.Much more difficult to learn how to use it. If this is neglected, then losing the anchor will not be a big problem, and making a braking device for every fishing trip is rather unprofitable. Therefore, it is necessary to understand how to fish so as not to lose the anchor.

How not to sink the holding device

Any body of water has its own type of bottom, which may differ in different areas of the same pond. Therefore, it is difficult to determine whether the device is located on a muddy or hard bottom, unless you try to study it. Alas, most fishermen do not do this. In order not to leave the braking device at the bottom of the pond, the following must be done:

- fix the holding device to the thickened part;

- equip it with a buoy;

- extract by means of a burrep.

How many anchors do you need

Usually, one holding device is enough for standard use of a PVC boat. The main thing is that the device is reliable, and the weather favors the fishing process.

However, it is advisable to take precautions and take an additional anchor with you, as they say, "just in case of a fireman." However, one must take into account pond bottom type. Sometimes you have to migrate from one pond to another, where the bottom tends to be completely different. That's why it is more reliable to have 2 holding devices: one should be designed for hard soil at the bottom, and the second for muddy.

How to make an anchor for a PVC boat with your own hands, see the next video.