How to make an awning for a PVC boat with your own hands?

It is sometimes almost impossible to find an awning that exactly matches the dimensional parameters of a certain modification of the boat. Yes, and it has a lot of cost. Therefore, if you have decided to get such an attribute of comfortable fishing, the best solution would be to sew an awning for a boat with your own hands, and besides, it is not difficult to implement it. It is only necessary to choose a piece of dense water-repellent fabric that is appropriate in size, duralumin, aluminum or PVC tubes for the supporting structure, a strong cord and eyelets (rings for threading ropes, ropes, cables through them).

Primary requirements

Regardless of whether the canopy is industrially made or homemade, it must meet certain requirements:

- the ability to protect the bow of the floating facility and things from precipitation;

- ensuring the protection of boat passengers from adverse climatic conditions;

- providing an optimal view for the one who controls the watercraft;

- providing proper conditions for fishing while the boat is in motion;

- proper protection of the PVC boat engine both during the parking period, during transportation, and during movement;

- the design must be as light as possible, not burden the watercraft;

- reliability is another fundamental requirement for the design in order to protect those in the boat from the branches of overhanging bushes and trees;

- ease of installation - as far as possible, all work should be done effortlessly and quickly.

At the same time, one should not forget about the quality of the material. If you use low-quality fabric, then during a long trip it is likely that the canopy will be damaged, and it is also difficult to foresee how events will unfold.

Necessary materials and tools

For the manufacture of the canopy, the following materials will be required. Moisture-repellent fabric made of durable fiber based on polyamide (nylon) or other material that is resistant to the influence of adverse meteorological phenomena. PVC fabric is not as comfortable as it does not allow oxygen to pass through and is heavier compared to other fabric options. When using tarpaulin fabric as a material for a canopy on a swimming facility it should be covered with waterproofing impregnation.

For visibility in the canopies, it is necessary use of viewing windows. In the windshield format, materials based on transparent polyethylene terephthalate (lavsan) or dense cellophane are practiced. A transparent PVC film is not recommended for use for absolute or greater coverage of a floating facility, since it does not allow oxygen to pass through. You will also need:

- rubber cord 1 meter long;

- a nylon cord with a cross section of 5-6 millimeters;

- eyelets with a diameter of approximately 1 centimeter;

- aluminum blanks for the supporting structure (if running canopy is being made);

- zipper fasteners (if a running awning-transformer is being created);

- plastic hooks;

- ropes;

- puncture needle.

To create a canopy, you will need the following tools:

- scissors, synthetic thread with a needle;

- tools and devices for working with aluminum blanks (electric drill, angle grinder, if a running canopy is being made).

How to make a frame?

Before proceeding with the pattern and sewing of the PVC awning, they are taken for the manufacture of the supporting structure. Usually create a U-shaped canopy, however, everything can depend on the degree of imagination. The main condition is that the frame is very lightweight and does not overload the watercraft. Aluminum tubes with a diameter of 15-30 millimeters are endowed with similar properties.

Taking into account the fact that the tubes will need to be bent, it is desirable to give preference to thick-walled options. Tubes with a thin wall can simply break off during work with them. An aluminum frame will not reduce the controllability and stability of the craft at all.

The dimensions of the supporting structure must match the overall parameters of the boat, and the height of the skeleton is determined by ease of control. It is important that the dead zone is located no further than 6-7 meters.

To bend an aluminum pipe, it makes sense to turn to professionals. They will do it carefully and at the proper level. Moreover, the work will be quite cheap.

If this is not possible, then you can carry out the procedure with your own hands, if you do everything correctly, besides, aluminum is a rather soft metal.In order to implement this process at a good level, it is necessary to fill the pipes with ordinary sand and drown them from both edges, for example, with a wooden chopstick. After that, you can take on the process of arching. The main thing is to find a foothold. Along with the, it is advisable to wrap the areas that will be affected with a worthless rag. This will protect the tubes from damage.

During bending, it is necessary to watch that the tube bends measuredly and in the same plane. Subsequently, all tubes are bent in proportion to the bend of the first, then all products will have the same configuration. For the first tube, you can make a template from ordinary wire and bend the first copy according to this template.

Upon completion of the creation of tubes of the required configuration, they take up the construction of vertical supports. On certain modifications of the boats, there is a special fitting for mounting the frame. With this option, the task is greatly simplified. Alas, some modifications are not equipped with similar devices. Therefore, you will need to buy and install them on your own.

All nodes for fixing the skeleton are carried out on bolts. The diameter is chosen in relation to the thickness of the tubes. If a variant with a diameter of no more than 25 millimeters is used, then bolts with a diameter of 6.0 millimeters will come in handy, and if the tube is thicker, then it is preferable to use bolts with a diameter of 8.0 millimeters. Be sure to use lock nuts in order to prevent spontaneous unwinding of the nuts. There are other methods to prevent the loosening of bolted connections.

During installation, close attention must be paid to the location of the mounting sections.They should be located at a certain distance from the PVC boat cylinders. This will protect them from damage during the use of the watercraft. Besides, all saw cuts and cuts of aluminum tubes must be carefully processed so that no burrs remain.

All fixation areas of the supporting structure should not be in contact with the PVC components of the inflatable boat in order to exclude the occurrence of emergency circumstances associated with damage to the rubber elements of the PVC boat, which can provoke an emergency on the water.

How to sew an awning?

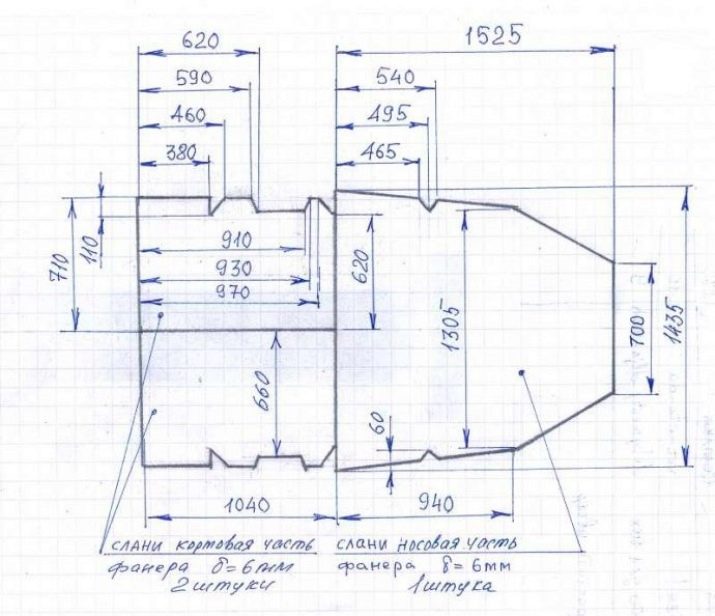

The point of departure in the production of any canopy begins with the precise measurement of the inflated watercraft, the transfer of its dimensions and the development of a project on paper, taking into account the scale. When planning a sample canopy, it is required to take into account the possibility of using oars. The procedure for manufacturing various types of awnings differs only in certain features and can be used not only for a parking shed, but also applied to other types (transport, running, bow, parking awning tent) used on PVC motor boats. For example, these differences are characteristic:

- for running canopy, which, when created with one's own hands, needs to be installed on a floating facility of a supporting structure;

- for nasal canopy, which in the manufacture needs the use of transparent materials - polyvinyl chloride, lavsan, dense cellophane, which can be used as windows.

The creation procedure consists of the following steps.

- Creation of drawings and patterns. For this purpose, dense cellophane, unnecessary pieces of matter, or another type of material can be used.The utility of the future canopy depends on the correctness of the patterns made. This will make it possible to calculate all possible errors. Unnecessary matter can be sewn, tried on, corrected. When the preliminary version of the canopy is prepared, you can begin to cut out the shelter. For any part of the canopy, an allowance must be made. In the process of cutting, you should be extremely careful and do not forget about the need to leave allowances along the edge to create a pass sleeve where a rope or cord made of rubber will be pushed through. They will be needed to tighten the entire structure. Then the edges of the canopy must be bent and glued with an auxiliary layer of material or stitched, tucking the fabric 2 centimeters.

- Transfer sketches on a moisture-repellent mat.

- Cutting and stitching the components of the canopy. Cross-linking zones must be reinforced with an additional layer of material. The sewing itself can be done both by hand and on a sewing machine. In parallel with this, work is underway to attach fittings, pockets, and specialized patches to the awning. After sewing is completed, the canopy must be installed on the supporting structure and left in this position until the morning.

- In order to be able to fix the canopy behind the eye-ring, eyelets are attached to the sleeves. It is desirable to strengthen the areas of their mounting with an additional layer of matter.

- A piece of rubber cord measuring 1 meter is screwed to a nylon cord with an artificial thread, after that, the junction is covered with polyurethane-based adhesive. The made rope is passed through the canopy sleeve. A rubber shock absorber is required to securely tighten the awning on the hull of the craft.

- To fix the canopy along the contour boats it is comfortable to use carabiners that are fixed to the fittings of the boat. Another method can also be used - fittings in the form of fungi are glued to the watercraft, for which the hinges of the canopy are hooked. These loops can be made from straps and used instead of a rubber rope harness.

The canopy for a PVC boat of our own is not only a cost saving, but also a more creative approach to the product, which can be made taking into account the unique design of the boat. For example, a do-it-yourself PVC boat canopy can have anchor pockets or a lifebuoy in its structure.

Pockets can also be used inside the curtain to hold all sorts of items.

How to make an awning for a boat with your own hands, see below.