Tables in the boat: why are they needed and how to do it yourself?

PVC boat table - a device installed along one of its sides. It is intended for installation of various devices necessary for fishing, arrangement of retaining grooves, storage of supplies, equipment and other fishing purposes. The constructive form of the table is determined by the parameters of the boat and its intended purpose. Depending on the presence or absence of these and other criteria, the table may have additional structural elements.

The main device installed on this table is an echo sounder - a device that displays the topography of the bottom of the reservoir. In this case, the design of the table should provide for the presence of appropriate fasteners.

Purpose and features

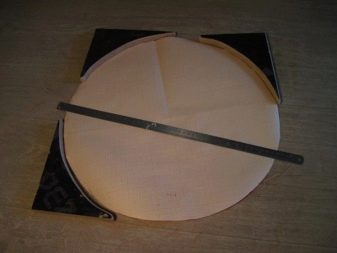

PVC boat table taking into account the peculiarities of its form. Such a boat has two onboard cylinders - inflatable sides with a round section. The roundness of their shape determines the arrangement of a semicircular cutout in the supporting walls of the table. The semicircle of this notch must coincide with the line of the bead circumference. In this case, the table supports will fit as tightly as possible to the surface of the boat, which will provide the best stability.

The supporting walls of the table can be trapezoidal or rectangular in shape (without taking into account the semicircular cutout).Their size and shape may be due to the presence of additional compartments under the table top - shelves, drawers or niches.

The characteristics and purpose of additional compartments also determine the degree of need for additional fasteners and reinforcements.

The top surface of the table can be provided with special holes. Among the list of names of their purpose, the following can be noted:

- coasters;

- grooves for the rod;

- recesses for holding gear.

Coasters allow you to install small containers with the possibility of stationary fixation. This makes it possible to use them effectively even with waves on the surface of the water.

Rod slots are usually placed along the edges of the table top or from the sides of the table. They can be made in the form of round holes with a diameter of at least 50 mm, cut into the plane of the table top. And they can also be made using special plastic clips, which are used to attach fan pipes to walls.

In both cases, a piece of gray sewer pipe used for sewerage can be used. The pipe is located at a certain angle, which allows the rod to be tilted in relation to the plane of the water. The upper edge of the pipe section usually coincides with the level of the top surface of the tabletop, and the lower one rests against the bottom of the boat or against special ledges that are part of the table.

To ensure the best use of the grooves for the rod, it is necessary to use a piece of pipe with a diameter of at least 50 mm. This diameter value will allow you to easily install and remove fishing rods and spinning rods with the handle down.The number of holes or pipes must be sufficient to accommodate all available fishing gear.

The fishing boat table may contain recesses or protruding limiters on its surface that allow you to safely contain the tackle that is used at the time of fishing. For long-term storage, these grooves will not work, but short-term preservation will provide the best.

For convenience, the surface of the table is equipped with special sides that prevent objects from falling from it. To improve functionality, the sides are made only on the sides, and the front (closer to the water) and inner (closer to the center of the boat) sides are not fenced. This allows you to easily maintain the surface of the table: remove from it the remnants of bait, small debris and other materials that contaminate the table top during operation.

To ensure that the absence of the front and inner sides does not lead to accidental loss of gear, they can be replaced with transverse elastic bands, stretching from one side of the tabletop to another. And it is also possible to equip special loops on the upper edges of the sides, to which elastic bands are attached, equipped with hooks or small carabiners along the edges. These elastic bands, stretched crosswise, prevent objects located on the surface of the table from falling off it.

Manufacturing

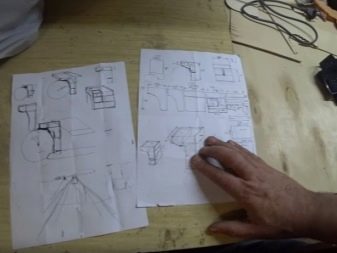

To make a table for a PVC boat with your own hands, you need to draw up detailed drawings. The stability of the table, as well as its functionality, will depend on how accurate they are, and how close the dimensional parameters are to real ones.

The main area to be depicted on the drawings is the area of contact between the side walls-supports of the table and the rounded surface of the side balloon of the boat. It is important to observe coincidence of the semicircle of the parts with the curved body. To achieve the best alignment, you can use a template. It will allow you to transfer the curve of the balloon to the blanks from which the details of the table will be cut. The pattern can be made from ordinary cardboard or other bendable material that can repeat the bend.

And you can also use special tools that allow you to mark curved lines.

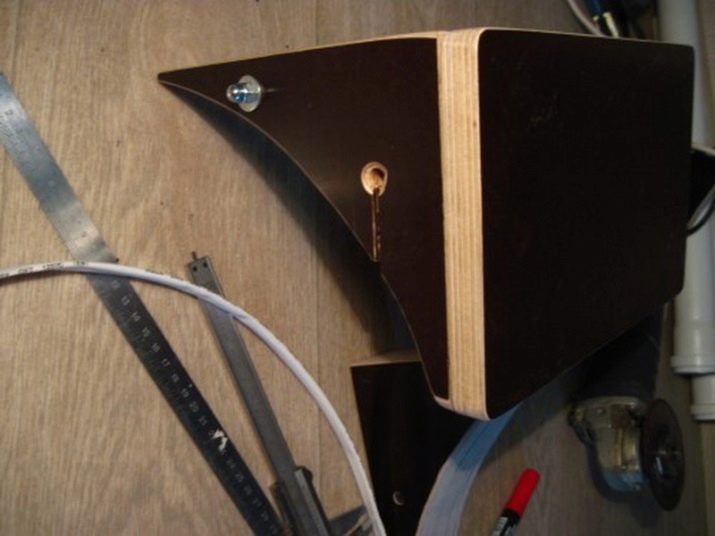

The side supports-walls of the table are made in an identical form. They must match in all dimensions. Particular attention should be paid to marking and arranging the hole for attaching the table to the lyktros - an edge cable running along the side, which is located inside a special tape glued to the surface of the boat's cylinder. It serves to strengthen the rigidity of the boat hull, attach landing pads and other equipment, including a table.

Mounting holes in the table supports must be located on the same level so that the table does not have a pronounced slope. The profile of these holes assumes their close location to the edge of the workpiece, and their diameter should exceed the diameter of the lyktros by no more than 2 mm.

The tabletop is made separately. Its configuration is calculated and designed taking into account the features of the intended purpose of the table. If necessary, holes are drilled in it for rod holders and grooves for coasters. The latter must be equipped with a "tray" that limits the immersion of the glass in the cup holder.

For convenience and aesthetics, the edges of the countertop must be cleaned of chips, burrs and other protruding sharp parts that appear after sawing. The edges should be sanded or glued with a plastic groove tape used in the manufacture of office tables (for its use you will need an electric router with a side cutter).

The connection of the supporting parts, countertops and other elements is made using self-tapping screws. To avoid cracking wood, It is worth drilling a mounting hole for each self-tapping screw. To reinforce the structure, you can use metal perforated corners, which are screwed on the inside of the connection of parts. For mounting the corners, self-tapping screws are used, the length of which will be sufficient and will allow them not to come out from the opposite side of the workpiece.

If necessary, additional partitions or shelves are equipped between the table supports. They can be used for long-term storage of gear, provisions, as well as rechargeable batteries for an echo sounder. The device itself should also be stored in a table. To do this, it is better to equip a closed box in its depth, the body of which will protect electrical equipment from moisture and mechanical damage. To simplify the operation of the echo sounder, it can be equipped on the surface of the table special mount for the device or holes through which it can be fixed.

Particular attention should be paid to equipping the table with electrical wiring. Its presence will allow you to charge the echo sounder from the battery without removing it from the tabletop. All connectors used for this purpose must be suitable for use in high humidity conditions and protected from water ingress.

Usage

This boat table can be made not only for a PVC boat with NDND, but also for a plastic or metal motor boat. Such a homemade table has a number of advantages over factory models:

- ease of manufacture;

- the minimum amount of materials and tools used;

- the possibility of choosing a form suitable for individual needs;

- the ability to move around the interior of the boat as needed.

To extend the life of the boat table, it must be protected from moisture. To do this, you can glue it with a fabric of a suitable color, and then varnish it. Another way of protection is impregnation with special anti-corrosion solutions and varnishing.

Making and using a boat table will simplify the fishing process and allow you to focus on catching fish, and not on side factors.

How to make a table for an inflatable boat with your own hands, see the following video.