How to make a do-it-yourself PVC boat trailer?

Every owner of an inflatable or PVC boat had to deal with the problem of transporting it somewhere. It is very inconvenient to do this in a passenger car, and special trailers for any type of boat cost a lot of money (an average cart will cost about 30,000 rubles). If you are not ready to spend a lot of money on a trailer, but you still need to transport the boat, all that remains is to make it yourself.

Basic design requirements

Like any other vehicle, trailers are subject to registration. Even if you assembled the trailer completely yourself, state registration with the traffic police is necessary. In order for everything to be successful, certain conditions must be met.

Chassis

It is very important to calculate the load distribution on each axle of the future boat cart. It should be like this so that approximately 66% of the total load falls on the front axle, and the remaining 34% on the rear. This condition is very important, because its non-observance leads to the fact that during transportation the rear of your car will be raised up. This will prevent you from properly transporting your watercraft.

An equally important task is calculate the center of gravity. He must be located in the middle of the future construction. This is necessary for the correct and even distribution of the weight of the boat on the axle.

To quickly calculate the center of gravity, place your boat on any log or log in such a way that it stands level and does not fall on its side. Mark with a marker on the boat the place where it balances stably.

If you have experience in designing, then it is quite possible to make the trailer universal or collapsible. You can make the winch, guides and stop removable, thereby turning the trolley into a real designer. Such a cart can be used not only for transporting boats, but also for any other purposes.

If your possession is not rubber or PVC, but a heavy metal boat, you should not make a cart on rollers. During transportation, these rollers will leave clearly visible dents. It would be better to lay the guides with some soft material (of course, you should not forget about strength either).

The size

First of all, it is necessary to observe the specific mandatory dimensions of the structure. Your structure in conjunction with the car must not exceed the following dimensions:

- hitch length - 20 meters;

- height - 3.8 meters;

- width - 2.2 meters.

You can make your cart smaller if necessary for the dimensions of the boat, but it is strictly forbidden to exceed these dimensions.

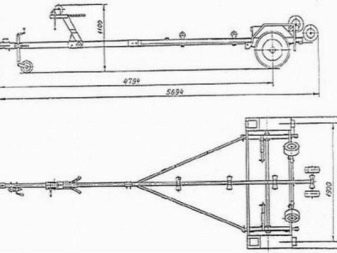

The following drawings are suitable for creating a trailer with a carrying capacity of more than 1 centner.

The main thing is not to miscalculate the size. It’s better to check and double-check everything so as not to waste money. If you compare the price tags, then you can buy all the materials that will be discussed below for less than 10,000 rubles.

Don't forget that it is necessary to calculate the dimensions of the future structure in such a way that the rollers are not under the boat or boat itself. If you do not comply with this condition, it will be much more difficult for you to lower the boat from the cart into the water.

It is equally important when calculating the dimensions to take into account the place from which you will drag the trailer into the water (to lift the boat onto it), perhaps there will be a great depth. However, if you prefer to fish in different places, then this advice is not so relevant for you.

Necessary materials and tools

In order to make a boat trailer yourself, you will have to purchase some materials. In addition to the main list, you will also need a torsion axle and a hitch. It will be better if you buy them ready-made with certificates. They are very difficult to manufacture, so it is better to entrust their manufacture to professionals.

The main list of components necessary for work:

- metal profile (thickness 4 mm, dimensions 60x40 mm) or metal pipe (thickness 3.5 mm, dimensions 80x40 mm);

- channel No. 12;

- metal sheet (thickness 2 mm);

- support leg;

- wings;

- wheels (according to the number of axles);

- wiring;

- light elements (headlights);

- winch;

- polyurethane or ready-made keel blocks;

- good paint and anti-corrosion coating.

Before production do not forget that you will need a welding machine, a set of tools for metal, or better, a special machine for working with metal. If you or your friends do not have such equipment, then you will have to call the masters for these works, which will significantly increase the price of the work. Depending on the level of the specialist, the price can increase up to two times.

During the process of purchasing materials, remember that do not choose thick-walled tubes and thick channels. They will greatly increase the mass of an empty cart, which will put even more stress on your car's engine, therefore, fuel consumption will also increase. The best solution would be to choose light, but high-quality and durable materials.

And also do not forget about the quality of materials. Although a do-it-yourself trailer is designed to save you money, if you want to use it for a long time without any problems and harm to your boat, buy good materials. The higher the quality, the longer you will enjoy your homemade product.

Manufacturing instructions

Let's take a look at the step-by-step instructions for making a homemade boat cart.

Frame manufacturing

Recall that absolutely all components of your frame (frame) must be fastened only by a welding machine. For the manufacture of the frame, metal profiles are used (or pipes, depending on what you could buy). Make holes in them, and then use the M12 bolts to align the future hitch and axle. Now carefully check the balance, as well as the perpendicularity of the center of the beam to the axis itself.

Frame equipment

Now you have to put and secure the cart on the support leg and cable. You can do without a support leg (aka steering wheel), but if you move your trailer with your hands, it will come in very handy. The lower handle will serve to adjust the height of the wheel, and the upper handle will help adjust the position relative to the tube. Before driving the car onto the track, raise the steering wheel and fix it in the groove of the pipe. When you need to move the trailer by hand, use the same levers to lower the wheel and turn in the direction you want.

The next step is to take a pipe with dimensions of 40x60 mm and weld a support mechanism for the winch from it. For the support of the wings and keel blocks, you should use the same material. With the help of metal strips (not less than 4 mm each), it will be necessary to fix the keel rollers. Of course, you need to fix them with a welding machine.

When you install keel blocks, do not forget to take into account one nuance: in order not to damage the roller with the keel of the boat, it must move on the axis extremely easily and gently.

Keel block length count so that the wheels themselves are under the longitudinal set of your boat. Thus, the bottom of the boat will be less deformed. In order to easily find the desired angle of installation of the wheels, it will be easiest to make a model of the bottom of your watercraft from fiberboard or chipboard. With this layout, simply adjust the rollers to the desired angle.

If you could not find the videos that suit you, you can make them yourself. To do this, you should pick up a small piece of polyurethane that needs to be processed on the machine, or manually grind 6 wheels out of it (2 - under the keel, 4 - under the side). For the manufacture of the axis of rotation itself, ordinary M14 bolts are needed. In the wheels themselves, drill holes according to the diameter of the bolts. Now take an angle of 50 and make smaller corners from it, in which you need to make holes and fasten them in a U-shape. They will serve as mounts for future axles.

Now that almost all the main components of the structure are fixed, a few more details need to be finalized. Take an anti-corrosion coating and carefully apply to all areas of the trailer. After that, you should wait for the time indicated on the package (until it dries completely), and then paint the entire structure.For this purpose, the most common enamel is suitable. The last step in the assembly is the laying of wires and the installation of light elements (stop lights, turn signals) and, of course, a special beam for fastening the number.

With proper operation, your trailer will serve for more than one year, if you have tried on its design. On the roads, do not forget that you are driving with a cart, so try to avoid deep holes and sharp turns in order to increase the life of the trailer.

How to convert a regular trailer

And now let's consider the alteration (modernization) of a conventional trailer for a cart for a boat.

If you do not want to spend money and time, you can save all this significantly. You can modify your regular car trailer to carry boats. To do this is quite simple. You will need all the same tools as in the previous instructions.

We install a regular trailer in a convenient place and begin to disassemble the body. You can throw away the body or give it to someone - it will no longer be useful to you. By standards, the drawbar of the design is not very large in length. To avoid hitting the nose of the boat or boat on your car while moving, you will need to lengthen it by about 1 meter (do not forget to provide for the possibility of its assembly and disassembly).

To increase wear resistance, special scarves should be used. You can make them very easily, you only need a pipe with dimensions of 40x40x4 mm. As a result of finalizing the frame, you should get a certain design.

The next step is to install the stop under the leg. Take the same profile pipe as in the last step. Buy exhaust rivets and rivet rubber. According to the reviews of people who have redesigned their trailer in this way, this idea is very successful.

To prevent the legs from tossing up during transportation, use a regular tie-down strap. Fix it with bolts or rivets directly on the beams of the structure. So you get a comfortable, and most importantly, durable fasteners.

Take the best strap, do not try to save on it, because if you damage the leg, it will have to be redone entirely, and this is much more expensive.

Now make or buy ready-made rollers. They should be installed and secured so that they can easily move around the frame. In order to find the exact location for them, you can use the layout. As already mentioned, the layout can be cut out of fiberboard or chipboard, and using it to find the desired angles and locations.

Don't forget to equip your cart with extra lights so you don't break the law. Some use old UAZ headlights for this. If your trailer already had good wiring, just stretch it to the new lamps, and if the wiring also had to be replaced, it is better to take a longer wire than you need, because you can always remove the excess length with the help of clamps under the trailer body.

If the previous wiring was good and you don't want to change it, you can buy a regular piece of wire and solder it to the old one. It is not recommended to use the twisting method - in this situation it will not be very reliable.

If you want to convert your main trailer into a boat cart, treat it accordingly. After all the treatments and upgrades, you will no longer be able to use your trailer for everyday purposes. Carefully measure the boat and all accessories when buying.

How to make a PVC boat trailer with your own hands, see the following video.

Cool, only the wheels are attached, it seems to me, flimsy ... maybe I'm wrong, but otherwise I'll use a lot for myself in the manufacture of my trailer for a boat.