Plastic boats: varieties, overview of models and selection rules

Fishing enthusiasts and tourists are often fond of relaxing on water bodies. Sometimes this type of recreation becomes simply irreplaceable for some people, and they think about how to make it more comfortable and interesting. In this case, it is recommended to purchase a watercraft. This item will help save energy and get new sensations from being on a lake or river. Currently, plastic boats are in great demand. And all because they are durable in operation and have a budget price.

Peculiarities

Naturally, any product has its own characteristics. There are also plastic boats. These products are made up of the following materials:

- glass mat;

- fiberglass;

- fiberglass.

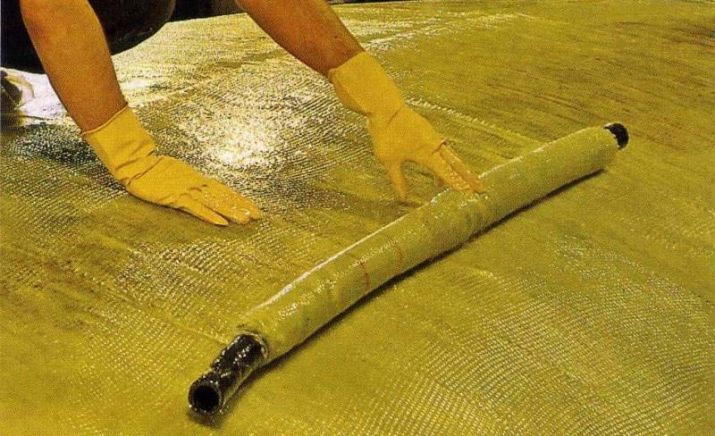

When the process of forming a boat starts, the fiberglass is reinforced, and polyester resin serves as the basis here.

More precisely, it can be noted that the plastic case of the product is produced in specially created standard matrices. This manufacturing technology is based on the principle of papier-mâché. The body of the plastic product is divided into 2 parts, between which there is an air space. This is how the unsinkability of the ship is ensured.The outer part of the case is protected by a special coating (gelcoat) from ultraviolet radiation and moisture, which destroy plastic.

Plastic boats are divided into the following types.

- People use open plastic boats for rowing. They are also popular with hunters and anglers. Only in these cases, a motor is installed on plastic products. This is done for the speed of movement from place to place. The length of open-type plastic boats can vary from 3 to 8 meters - this is a standard value. The motors on them are suitable for those that have a power of 2.5 to 300 horsepower. If desired, you can also install a remote control on the engine. To increase the space inside the boat, fuel tanks are usually built into the body of the product.

It is only necessary to remember that these vessels are mainly used where there is no strong current (for example, a lake or a pond).

- Next come boats with a decked bow, which are distinguished by an original control system. For these products, the installation of one or two motors at once is provided. Moreover, such models can be equipped with a stationary motor and additionally equipped with remote control of the engine. It also provides for such nuances as a cabin in the bow (which makes it possible to hide from the weather), built-in fuel tanks (saving internal space). If you want to mount additional elements in the case, then this will only emphasize your individuality.

Also, boats of this type are equipped with fences. This was done to increase the safety of being on the deck. Therefore, on these models, you can safely go to open water (sea, full-flowing river).

- Cabin plastic boats and boats have convenience and excellent seaworthiness. They are the most autonomous compared to other models. That is why these products can make long walks on the sea. They are quite roomy (you can take on board from 2-3 to 8 people).

There are sleeping places, as well as a bathroom and a kitchen space. Sometimes, in order to reduce the cost of goods, manufacturers install running tents on such boats and boats.

Of the advantages of plastic boats, the following can be noted.

- Presentable appearance. Their rounded contours, shiny hulls beckon to travel. Sparkling surfaces make plastic boats irresistible in comparison with other products of this direction.

- Pretty low pricewhen compared with models that are made by welding or riveting.

Of course, there are also disadvantages:

- This is primarily abrasive wear. The gelcoat that covers the outside of the boat is easily rubbed off on the sand of the shore (especially the keel). Therefore, it is necessary to stick the so-called keelguard on the keel.

- Next on the list is the hydrolysis of fiberglass. However, keep in mind that in our time, manufacturers have learned to make the gelcoat much tighter, and therefore, this drawback has become less noticeable.

- There are also problems with winter storage. But they are easily removed if you have a special heated room.

- Last but not least is the toxicity of plastic. Styrene, which is released from it, can lead to various human diseases.

Each product has its own disadvantages and advantages, so it is better to act on the principle of "forewarned is forearmed".

Comparison with other materials

At the moment, manufacturers offer a large number of products made on the basis of different technologies and from various materials. Let's try to make a small comparative review.

Models made of non-metal are more plastic. For example, when a fiberglass boat hits a snag on the move, this material can easily win back and there will be no trace of the impact. And if, nevertheless, a chip appears, then it can be easily eliminated with the help of automotive putty. What can not be said about aluminum or another product. In any collision, dents that are difficult to repair are difficult to avoid. So that in this case, a plastic boat is better than an aluminum or riveted one.

The next question is mooring with the bow on the gravel shore. Plastic in this case may be inferior to aluminum. However, everything is not so simple here either. For example, a glued keelguard will easily solve this problem. And if you moor more carefully, then this type of problem will not arise soon.

Plastic does not corrode, which cannot be said about metal products. The hull of the plastic vessel does not require painting. Metal models need a special approach. During their current repair, it is necessary to use special primers and paints that do not contain copper or zinc (such materials are more expensive than others).

Unlike riveting and aluminum products, plastic boats are subject to quick repair. For its implementation, it is enough to have an auto-putty for plastic bumpers, sandpaper and a can of paint (it is advisable to choose the color).

The plastic hull of the boat is quite durable, unlike the aluminum one (it is enough to run into a stone and a crack will appear).Dents when hitting stones on the composite case practically do not appear. And in order for it to crack, it must be subjected to serious tests.

Metal boats get holes when they are transported overland from place to place. It is enough to put the product wrong, and it will crack. To repair it, you need to find a competent master who can fix the problem. There are no such problems with plastic boats.

In addition, plastic is cheaper, products from it can be formed at will and any layout can be performed. And this allows you to achieve the optimal shape of the model, which will be the most hydrodynamic. Metal boats require the most powerful engine possible due to the weight and resistance to water flow that rivets and welds provide.

However, it must be remembered that in the open air in winter, composite materials are quickly destroyed. If you walk on the deck in boots, then it will be covered with small scratches, through which, over time, water will begin to penetrate into the hull.

Therefore, if you are purchasing a boat for fishing and a purely male company, then it is better to choose products made of metal or other material.

Composite materials are more suitable for aesthetic, comfortable and ergonomic use. A boat or boat made of plastic is part of the world of a person who strives for perfection.

Kinds

To date, manufacturers offer a huge number of different models. There are motor boats, rowing boats and even collapsible boats. The choice of model directly depends on the needs of the buyer.

Consider in order the main types of boats.

- Motor boats can be made of any suitable material: PVC, fiberglass, metal, wood. PVC boats are reinforced and non-reinforced. As you can see, there is no limit to the diversity in this matter. Based on the feedback from experienced consumers, if you want to purchase an inflatable model, it is better to choose a product made of reinforced material - polyvinyl chloride. Unreinforced material has low strength, which means that such models can fail on water.

- Folding boats, and there are also collapsible ones. These models are in great demand. Some craftsmen assemble such models with their own hands according to their own drawings, while other water lovers prefer to buy finished products. Folding boat modules are easy to assemble and disassemble. They can be connected using special clips (like the Origo folding boat).

These boats are easy to transport from place to place.

- Rowing boats are considered slow-moving and are suitable for a relaxing holiday or fishing. They are walking models, because they do not raise splashes when moving. On these products, long-distance swims are undesirable. To move on such boats on the water, the owners need to stock up on oars and have good physical data.

- Single and double inflatable boats in most cases do not require registration. They weigh about 15 kg and fit easily into a backpack. The design of these products is made in such a way that if one compartment is punctured, the vessel will still remain afloat.

- With inflatable boards. As a result of the connection of a rigid motor boat with an inflatable one, the RIB model was obtained (it has a plastic or aluminum bottom with multi-chamber inflatable PVC boards).It is considered an unsinkable vessel and can move even in shallow water.

It is widely used for patrolling water areas, in tourism and sports.

- Boats with high sides are used where frequent transportation of heavy loads is required (each side has its own weight load criteria). In order to choose the right boat for such purposes, it is necessary to take into account not only the distance from the keel to the top of the side amidships, but also the minimum freeboard (measured by the minimum place, which is determined by the full permitted load).

Manufacturer rating

Russian-made boats are in no way inferior to imported ones. To date, there are a very large number of enterprises that are engaged in the production of watercraft. Consider the manufacturers who are the most famous.

- LLC "Sparta" produces plastic boats. For example, the boat "Spray" 330 has a double-hull design. It is used as a rowboat, you can install a 5 hp outboard motor. With.

- The Saitov shipbuilding company is located in the Kirov region. Produces fiberglass boats and boats "Bester". For example, the aluminum boat "Bester-450" under the tiller can take on board about 4 people, and the recommended motor power here ranges from 15 to 30 horsepower.

- Ufa factory of PVC inflatable boats "Helios" produces lightweight products for the motor, which are highly appreciated by customers for their excellent quality.

- Yaroslavl boats LLC specializes in the production of classic rowing and motor boats, as well as kayaks.

- Motor boat factory "Solar" located in Berdsk and produces PVC inflatable motor boats.

- The boat manufacturer "Hunter" is located in St. Petersburg and has been operating since 2009. It produces models that are equipped with a protective mechanism for the keel and a spacious cockpit. These products can be equipped with a 10 hp motor. With.

- Company "Triton-LTD" has been operating on the Russian market since 1991. It is a leader in the production of collapsible ships.

- Stroybot LLC, Sevastopol, manufactures small boats made of fiberglass and aluminum.

- Manufacturer of inflatable boats "Poseidon" (St. Petersburg, Russia) produces products that have proven themselves only from the best side.

- CJSC "Pskov boat shipyard" produces small vessels made of fiberglass. The enterprise produces boats of well-known St. Petersburg designers Yu. A. Sitnikov and B. N. Ershov. There are also own developments - this is the Seliger lineup and the Astra boat.

- Pelican Co. manufactures PVC inflatable boats which are of high quality.

- OOO "Argo" produces PVC boats and rubber boats of the Argonaut brand. There are more than 45 modifications.

- Trading House "Ural-Expedition" is engaged in the production of PVC inflatable boats, catamarans and camping equipment.

- Enigma Company (Dolgoprudny, Moscow Region) specializes in the construction of boats of various models and catamarans. All vessels are equipped with outboard motors. The boats of the Enigma shipyard are hand-assembled, which guarantees high quality.

Cases of products are made of fiberglass or aluminum and fiberglass.

- Boat manufacturer "Las" (St. Petersburg) sells boats that are distinguished by their reliability.

- The Samara plant of motor boats "Salyut" has been producing since 2004. motor aluminum boats under the trademark of the same name.

Criterias of choice

First you need to decide on the purpose of using the craft.Then you can safely select it according to size. A small boat is suitable for those who like to relax alone. In other cases, you need to consider the following.

- For fishing or hunting, it is better to choose models that are reliable. In addition, gear and other items should be easily placed in the craft.

- For a large company, the boat must be roomy. This should be taken into account if you are going to relax with the whole family or together with a large number of friends. Choose models with a powerful motor and longer ones. Of course, such a vessel should be the most durable.

To make the right choice, take into account the experience of experienced people.

- If the boat is located next to a body of water, then its weight and transportation can be ignored. If you have to transport the boat from place to place every time, then get a lighter product (a plastic boat is ideal for this).

- To transport the vessel, you need to buy a device on wheels, which is easily attached to the car with a special device.

- It is worth considering in advance the amount of money that you are ready to invest not only in the purchase, but also in the maintenance of the vessel. Please note that the maintenance of a watercraft includes the payment of taxes and responsibility for behavior on the water.

People who want to buy a watercraft have different desires, goals, needs and requests. Someone is going to make money with their ship. For example, entrepreneurs ride vacationers on boats and make good money on it.

Others use boats to get to places where they can catch a lot of fish or make a successful hunt. In such cases, the reliability and patency of the craft is the most important criterion.Your life and the lives of others will depend on it.

Care rules

In winter, boats are mostly not operated. Therefore, they are "canned". The further operation of the boat will depend on the correctness of this process. So, what needs to be done so that your ship does not sink in the spring.

- Rinse the vessel well to remove mud or salt water. If the vessel is made of plastic, then it is necessary to clean its hull from fatty impurities.

- Dismantle tooling and engine.

- The engine must be inspected and preventive work carried out in the form of repair and lubrication procedures (lubricate all body bolts and nuts with grease so that they do not rust in cold weather).

- During the operation of the vessel, various cracks and chips appear on the surface of the hull. Needs a thorough renovation. If the damage is minor, fix it yourself. If you have more serious problems, it is better to seek help from a specialist. Plastic boats are easily repaired with epoxy. Just follow the exact instructions for diluting and drying it. After the work has been done, the place of the chip or crack must be covered and painted over.

- Decide on a storage location. It must meet all requirements. Do not leave the boat in a damp room. Storing a boat, especially a plastic one, in the open will be disastrous for her.

- If there is no special room for storing the boat, then you will have to resort to other actions that require a careful approach. To get started, make wooden supports (goats) for your watercraft. This will raise the boat some distance off the ground. Place the product on them with the keel up (this is a prerequisite).It is best to make a small canopy over the vessel from the weather, in extreme cases, “pack” it on all sides in a tarpaulin.

Remember that a boat needs careful year-round maintenance, just like any other thing. The first requirement is to monitor the cleanliness of the bottom and the entire hull as a whole. To do this, it is enough to rinse the vessel with clean water. The integrity of the case is also of great importance. To keep everything in order, check your watercraft for cracks and chips. If there are any, then troubleshoot in time.

So that your boat does not lose its dignity, treat it with care during operation. It is worth mooring to rocky shores at low speed so as not to damage the bottom of the product.

About the better plastic boats, see the following video.