Adhesive for repairing PVC boats: varieties, recommendations for selection and use

One of the main attributes, without which a modern angler practically cannot do, is a reliable swimming facility. Most often we are talking about a boat made of polyvinyl chloride. It is convenient, practical, has good technical characteristics, it is convenient to transport it and with proper care it will last for many years.

But no matter how carefully a person treats this watercraft, there are frequent cases of its breakdowns and various kinds of damage. Therefore, you should figure out which patch is better to make and what kind of PVC boat repair glue to choose so that it is always at hand.

Peculiarities

The use of high-quality glue will allow you to repair the boat and extend its operation. It is usually recommended to use the one that comes in the repair kit. But it ends pretty quickly due to the small volume of the tube, so you have to buy a new one.

To repair damage to a PVC boat, it would be better to use compounds where the composition contains natural components such as resin and rubber. They will allow you to make the seam as elastic as possible and save the place of gluing from the harmful effects of water.

But whatever glue is used, the most important thing is to comply with all the rules for its use.

Kinds

To restore the integrity of the boat, there are two categories of adhesives:

- one-component;

- polyurethane;

- two-component.

The first category is considered the most suitable for repairing physical damage to PVC boats. This can be explained by the fact that such a composition was specially created for the repair of rubberized materials that are the basis of boats. Such glue has high elasticity and good strength. It is also distinguished by immunity to temperature changes, which allows you to get a durable and high-quality seam.

Its analogue can be called polyurethane glue. In general, it has similar features. Its only differences from the one-component one are transparency and the absence of yellowing over time, due to which the aesthetic appeal of the boat is maintained.

Two-component formulations have a more complex composition. In addition to the polyurethane base, they also contain organic solvents, as well as wax. This combination of components allows you to give it high elasticity, strength and reliability.

Bostik Vinycol 1520 is regarded by many anglers and boat owners as one of the best on the market. And he belongs in that category.

Manufacturers overview

In specialized stores you can find a large number of compositions for the repair of PVC boats. It will not be superfluous to characterize the most popular of them.

"Moment"

One of the most famous domestic options is Moment. This brand has proven itself and is considered very reliable. The advantages of this composition are:

- availability;

- water resistance;

- Ease of use.

The disadvantages can be called:

- high toxicity;

- susceptibility to decay upon contact with various solvents;

- intolerance to ultraviolet radiation.

"Liquid patch"

The next adhesive composition is called "Liquid Patch". He appeared relatively recently, but has already managed to prove himself perfectly. This is a polyvinyl chloride suspension with the addition of strong solvents. It acts like this - solvents corrode the base of the boat around the damage, and the reagents restore the ductility of the tissues. When the patch dries, the boat appears to be solid.

Advantages of this glue:

- ease of use;

- the ability to seal even internal seams;

- no need to use a brush or hair dryer;

- they can repair punctures and crevices without patches.

Flaws:

- high toxicity;

- few places for sale;

- not suitable for repairing large damages;

- they can't repair the hardware.

"Uranus"

The next composition, which should be said - "Uranus". This is a polyurethane adhesive designed to work with elastic materials. It is made on the basis of synthetic rubber and organic solvents. It is colorless and has a pink or yellowish tint. Dries quickly.

Its advantages:

- has the highest resistance to water;

- made specifically for polyurethane;

- makes the glue line elastic, colorless and as invisible as possible;

- after drying, it is not dangerous to humans.

Flaws:

- very toxic, therefore, when applying it, you should have personal protective equipment;

- quite flammable.

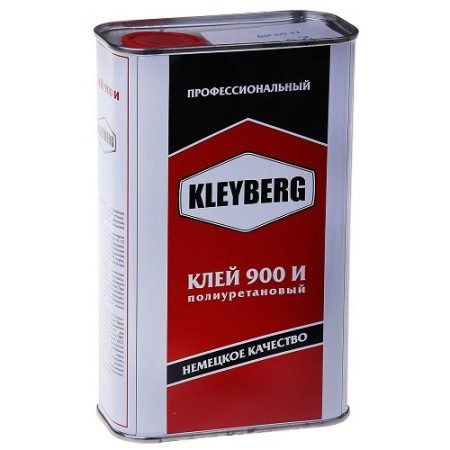

Kleyberg

Another adhesive that deserves attention is Kleyberg. It has a polyurethane composition with organic type solvents and stabilizing additives. Its advantages:

- water resistance;

- high density;

- high-quality adhesion to the surface.

Minuses:

- at low temperatures, the bonding properties are reduced to zero;

- it should be stored at a temperature not higher than +15 degrees.

Sintacoll

You should pay attention to the adhesive called Sintacoll, which is a one-component composition. Its advantages:

- seizes very quickly;

- sun resistant.

Flaws:

- so that the seam obtained with this adhesive is resistant to temperature extremes and hydrolysis, it must be mixed with a hardener before use;

- if the instructions for use are not followed exactly, the adhesive properties of Sintacoll will be greatly reduced.

Texacol

Another popular brand is Texacol. Its composition ensures maximum tenacity of PVC and polyurethane materials. It is produced in the form of one-component and two-component compositions, which significantly expands the possibilities of its application. It comes with a special hardener.

Its advantages:

- reliable adhesion to surfaces;

- it does not need to be heated with a hair dryer;

- withstands prolonged exposure to water;

- resistant to temperature changes.

The only drawback is that in order for the patch to be heat-resistant, the adhesive must be diluted with a special hardener before application.

Bostik Vinycol 1520

It should be said about the Bostik Vinycol 1520 mentioned above. It is made from rubber and organic solvent and belongs to the category of two-component. Its advantages are:

- high adhesion;

- excellent adhesive strength;

- good resistance to severe temperature changes;

- resistance to contact with solvents;

- maintaining their qualities at high humidity.

Its disadvantage can only be called high toxicity, which is why it is better not to use it without personal protective equipment.

reactor

Another glue that deserves the attention of consumers is called Reaktor. It is sold in tubes of 15 milliliters and allows you to eliminate small punctures, cuts and scuffs.

Pros:

- easy to use;

- less toxic than analogues.

Flaws:

- not suitable for repairing serious damage;

- It does not have very high water resistance.

"Master"

Another glue that is very popular is Master. Sold in a compact tube that fits easily into a box with a repair kit. It is a one-component waterproof substance based on polyurethane, which is made of rubber.

Its advantages:

- seizes very quickly;

- small size of the tube;

- suitable for patch repairs.

Minuses:

- it can only be used in a warm room at a temperature of at least +18 degrees;

- one tube is not enough to repair serious damage to a watercraft.

"RK-2"

Quite often, owners of PVC boats use RK-2 glue. It is excellent for working with most categories of rubber, including PVC. Its main advantages can be called:

- immunity to water;

- excellent resistance to temperature changes;

- creates an elastic and very reliable seam.

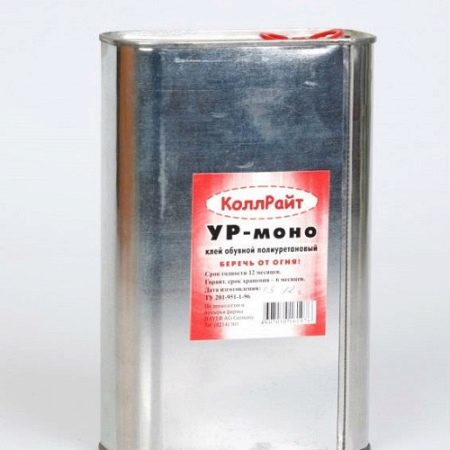

"UR-mono"

Another interesting option is a glue called "UR-mono". It refers to one-component means. It can be used without the need to add any additional hardeners. Its advantages can be called:

- the highest degree of water resistance;

- immunity to ultraviolet radiation;

- low toxicity when used.

900I

Another popular glue is 900I. It is made of polyurethane. The extent of its use is extremely extensive: balls, rubber soles, and so on. Can also be used for PVC boats. Its advantage will be excellent resistance to various oils, acids, gasoline and water.

Penosil Fix Go

The last adhesive composition that I want to talk about is called Penosil Fix Go. The manufacturer positions it as a cold weld made from epoxy substances.

Pros:

- hardens very quickly;

- excellent for bonding PVC surfaces.

How to choose?

In order to choose the highest quality adhesive for repair, these aspects must be taken into account.

- Drying time should be minimal, because in natural conditions there is no way to wait a long time until the glue hardens.

- If it is made of cyanoacrylate, then it cannot be used. Despite the ability to glue anything, the effect of such a composition will last a very short time.

- If the composition is made of polyurethane or chloropropylene, then this is also not a suitable solution for the case under consideration. Their sensitivity to moisture is very high, because of which the seam will be very fragile and unreliable.

- Versatility - not the most correct requirement in this case. It would be better to use glue that is only for fixing PVC boats.

- Heat resistance is an extremely important feature. It is better to choose products that can withstand large temperature changes.

- The cost of good glue is high. But in this case, it is better not to try to save money and give preference to an expensive, but really effective composition.

- Glue quality also matters. This setting is easy to check. It is enough just to apply a little glue on something and leave it for 5 minutes, then check it for stickiness.If it is of poor quality, it will stick to your finger.

- Moisture resistance. The glue must withstand the effects of water, because the use of the product takes place on the pond.

- Durability. The seam made should not lose strength with prolonged use of the product.

- Elasticity. The glue joint must resist stretching perfectly.

Usage Tips

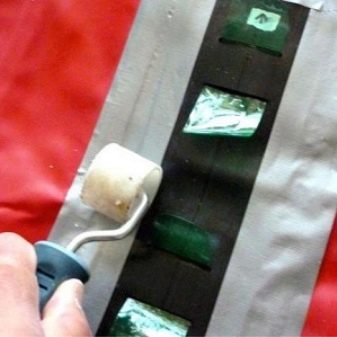

It is necessary to strictly follow the algorithm of actions specified in the instructions for the adhesive composition. A number of means lose their properties if a person, when used, deviates from the norms that are prescribed in them. To get a really high-quality seam, especially if patches are glued, the glued surfaces must be cleaned with coarse-grained emery. After that, they must be cleaned with acetone or a solvent and dried well. So that the load on the adhesive composition is not so strong, it is possible to pull together large gaps before gluing using nylon threads.

For spot repairs, it is best to use a liquid patch. If it is required to repair boat fittings, then it is better to use adhesive compositions of a single-component group.

And if we are talking about stationary repairs, then it is better to use a two-component professional adhesive.

If repairs are carried out on shore, then it is better to give preference to road tubes. In addition, it will be important to observe the temperature regime and apply glue for repairing PVC boats only at temperatures above +15 degrees. Direct sunlight should be avoided. When applying the adhesive composition, bends and various kinds of bubbles should be avoided. If you need to seal places where there are folds, then it is better to entrust this to professionals.

If the glue gets on your hands, then it can be removed with acetone or gasoline.It is enough to apply a small amount of them to the area where the adhesive has got, and wipe it off with a rag. After that it is required Wash your hands very thoroughly with soap and dry them with a towel.

For information on how to properly use PVC boat glue, see the following video.