Cutters for hardware manicure

All industries aimed at improving the quality of service have been developing rapidly in recent years. It is quite natural that new technical developments are increasingly being used in the beauty industry. In accordance with this trend, a hardware manicure has come into our lives to replace the traditional trimmed manicure.

What it is?

Hardware manicure, in comparison with the traditional edged one, has made a significant step forward both for masters and for those who use this service. This technical improvement allows the master to significantly improve the quality of his work. As for clients, for them, hardware manicure provides real comfort and safety: the fear of pain, cuts and long-term non-healing wounds is a thing of the past.

Compared with trimmed manicure, hardware has a number of advantages:

- long-term results with minimal time investment;

- exclusion of getting fungal diseases;

- guaranteed improvement in the quality of the nail plate due to quick correction of its shape and soft polishing;

- absence of microcracks and cuts;

- painless procedure and its safety;

- the possibility of treating problem nails.

Mastering the technique of performing hardware manicure is quite a feasible task. It is especially relevant for those who cannot often do trimming manicure due to exfoliating, breaking or extended nails.

Description

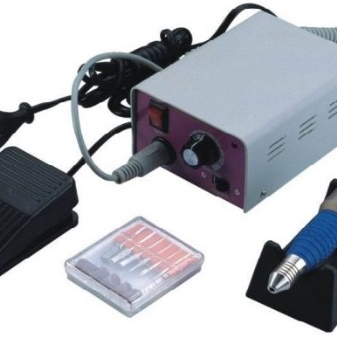

In order to master the technique of home hardware manicure, you need to thoroughly study the appropriate equipment. First of all, you will have to purchase a specialized device called a milling cutter, or a milling machine.

Currently, there are a large number of various milling cutters on sale, which differ in technical characteristics and, accordingly, in a set of specific functions.

When buying a milling cutter, experts recommend considering such models that will help you solve your very specific tasks. This means that it is wiser for beginners to refuse to purchase some newfangled multifunctional device for a while.

When choosing a router, be sure to do the following:

- clearly define the functional purpose of the device (only for manicure or for manicure and pedicure);

- make a decision in advance regarding the range of its use (only for personal use or for salon use);

- carefully read the technical characteristics of the router (especially noteworthy are such moments as the warranty period, the presence of protection against possible overheating, etc.);

- evaluate the device in question in terms of the convenience of working with it (milling cutter weight, wire length, etc.);

- check whether the supplied set of cutters allows you to carry out the hardware manicure procedure in full.

Before mastering the technological skills of hardware manicure, you need to study the replaceable components that come with the milling machine. These include nozzles of various purposes (in the form of cutters, drills). In this case, nozzles can be included in the kit or sold separately.

In the field of hardware manicure, various nozzles are used, which differ from each other in the material used for their production, as well as in their functional specialization, and, accordingly, in their design characteristics.

What are needed?

In general, for pedicures and manicures performed with a milling cutter, a variety of nozzles in large quantities are required. With the help of special nozzles inserted into the milling cutter, the cuticle and lateral ridges, the free edge and the surface of the nail are processed. Special nozzles are also used to grind rough skin and remove an ingrown nail.

Processing and design of nails in all its diversity - including the care of acrylic, gel and false nails, requires the ability to work competently using the necessary nozzles.

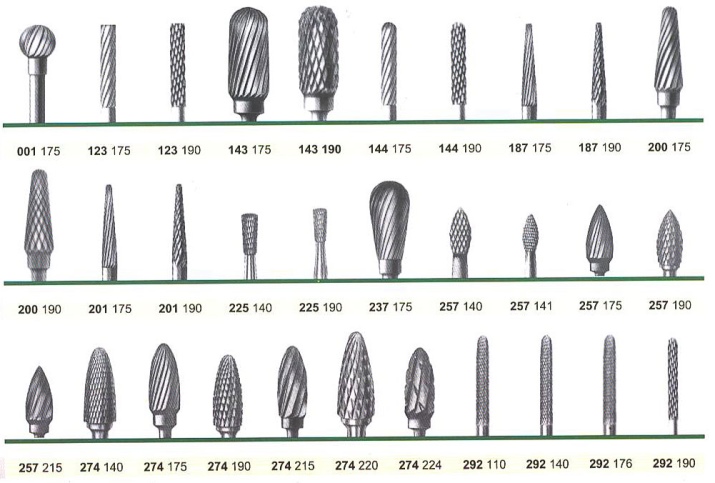

The main tool for performing hardware manicure is a cutter. It is important to know that the purpose of the cutter determines its shape.

In practice, cutters of 4 groups are usually used, differing in terms of a specific shape. In accordance with this, the following groups of cutters are distinguished:

- blunt;

- narrow-ended;

- with a spherical end;

- with a "corn-like" end.

blunt cutter, resembling a cone or cylinder in appearance, is used during stripping, when it is necessary to lift the cuticle on the nail, clean the nail plate, and also remove the previous coating.

Narrow End Mill with a sharp or rounded tip cleans the lateral sinuses and the area under the cuticle, removing pterygium from them.

Ball nose cutter has the shape of a ball and performs a particularly important function: it cleans the raised cuticle and carries out its subsequent polishing.

Cutter with "corn-like" end, known as "corn", is able to gently remove even a thick layer of coating on artificial nails and does it easily, without causing the slightest damage.

Since the cutters have a specific functional purpose, they have different characteristics for a number of indicators, which include such as the type of abrasiveness, rotation speed, cutter diameter.

Kinds

Cutters are usually divided into certain types depending on the material used for their manufacture. Based on this differential feature, there are such types of cutters as:

- corundum;

- diamond;

- ceramic;

- carbide;

- pomegranate;

- silicon carbide;

- silicone;

- steel.

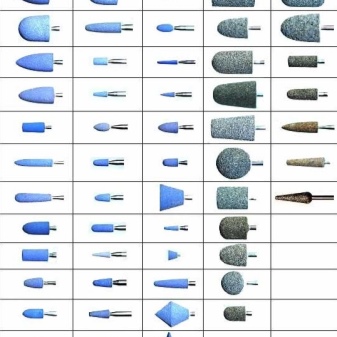

Corundum cutters are resistant to elevated temperatures and have a variety of abrasive characteristics. In the process of polishing both nails and skin, corundum tools with soft and medium hardness should be used.

When performing hardware manicure, diamond nozzles are traditionally used, which are distinguished by a wide variety of shapes, sizes and functions. Especially popular are such diamond nozzles as "flame" and "bullet": they can effectively treat the cuticle, rough skin, the free edge of the nail plate, side ridges, and, if necessary, calluses. These diamond tips also work well with the correction of artificial nail coatings.

Ceramic nozzles, which are distinguished by hardness, effectively process cracked nail plates along with side rollers and grind rough skin. Ceramic cutters are characterized by structural simplicity and safety. They also heat up less than metal ones.

When performing hardware manicure procedures, carbide cutters are also widely used, which differ in special notch options. Nozzles of small diameter carefully process the cuticle, they are no less good in the process of adjusting the gel, gel polish and acrylic coating.

Silicone nail tips (also known as polishers) are primarily used when natural nails are being treated. At the same time, they are widely used when working with soft artificial turf. In terms of abrasiveness, silicone nozzles are divided into hard, medium hard and finishing.

There is also a special, combined, version of the nozzles: the material for their manufacture is silicone carbide. It is he who ensures the transformation of silicone polishers into harder nozzles. At the same time, high-quality and fast polishing of nails is achieved through a combination of combined and silicone polishers of different hardness.

Pomegranate cutters are of high quality and are intended for a variety of manicure operations. Such types of nozzles as “garnet flame”, “garnet ball”, “garnet drop” and others from this series are characterized by increased demand.

Silicon carbide nozzles are considered common: nozzles of this type are disposable caps with a rubber base.They are also convenient to use when performing one or another design work on the nails. Some nozzles perform narrow functions. In particular, a tungsten burr with a titanium face coating is used when it is necessary to carry out the upper or inner correction of an acrylic or gel coating.

Purpose

In order to learn to be well versed in the variety of cutters, you need to know that in practice, masters rely on their classification, which is based on the functional purpose of the tool. This classification allows you to avoid mistakes directly when performing manicure procedures, and also serves as a reliable base for orientation in a rapidly updated range of nozzles.

An overview of the main functions of nozzles shows that, based on this criterion, they are divided into 5 types. Cutters include:

- steel (appointment - removal of the cuticle and treatment of the periungual zone);

- ceramic or corundum, as a more modern analogue of ceramic (narrow purpose - non-rigid removal of the cuticle, as well as shaping the nail);

- carbide (high-quality artificial nails are processed);

- diamond (broad purpose - use in both manicure and pedicure procedures, and traditional use - hardware correction of nails with a gel or acrylic coating);

- polishers (narrow specialization - polishing of both natural and extended nails).

Since today there are a large number of different nozzles that differ in a number of parameters, it is very difficult to choose the right set without special training without the appropriate experience.In this matter, it is most reliable to rely on the advice of professionals.

How to choose?

The complexity of selecting the necessary nozzles is explained not only by the variety of tools available for sale, but also by the difficulty of determining how high-quality samples are offered to you.

When choosing cutters and nozzles for hardware manicure, one must proceed from the fact that a high-quality manicure can be done only with high-quality tools. Therefore, it is better to buy a complete set from a reputable manufacturer.

If you decide to select components yourself, you should take into account a few tips from professionals, following which is mandatory. Briefly they can be summarized as follows:

- start mastering hardware manicure using safer ceramic cutters;

- when processing nails with diamond cutters, remove the cuticle using small nozzles;

- to remove calluses, use larger carbide cutters;

- use special polishers and grinders, starting polishing with the hardest cutter and finishing this operation with the softest one available.

Proper selection of cutters and their application in the correct sequence in compliance with all safety requirements should be considered as a prerequisite for achieving the optimal result of your work.

How to use?

In order to effectively use the router, first of all, you need to decide on a set of nozzles. Masters recommend purchasing nozzles to solve specific current problems, and not to collect their collection. It is necessary to master technical skills step by step, starting with simpler and more necessary procedures for you.

How to insert into the device?

For those who are going to do a hardware manicure on their own, the question often arises of how to properly insert the nozzle into the machine. Some of the difficulties that this simple, in fact, operation can cause, are to some extent explained by the fact that there are 3 types of clamps:

- manual;

- semi-automatic;

- automatic.

The most common of these are manual and semi-automatic. As for the automatic clamp, it is used quite rarely, as a rule, in devices equipped with a built-in vacuum cleaner.

The most convenient clamp is considered automatic. Fixing the cutter is carried out in the simplest way: it is inserted into the clamp, and its further fixation occurs automatically.

In a semi-automatic device, to fix or change the nozzle, the handle must be turned until it clicks, moving clockwise. This ensures the opening of the clamp, which allows you to change the nozzle. After replacing the nozzle, you need to perform the last operation - turn the section in the opposite direction.

As for the manual clamp, it is quite easy to open and close. The nozzle is usually inserted effortlessly if you press the button located on the body. After that, you need to unscrew the washer. In this case, you need to know that the part of the handle on which the nozzle is fixed performs the function of a clamp. To close the clamp, you must press the same button, wait for it to sink and tighten the washer tightly.

According to professional craftsmen, all these clamps work reliably, and the presence of a certain type of clamp in the machine is usually determined by the specifics of its model.

How to do a manicure?

In order to do a hardware manicure at home, you need to know the relevant rules for its implementation, as well as the features of the device intended for home use. The fact is that home models of devices differ from professional devices in a lower speed of rotation of the nozzles.

It should also be borne in mind that home appliances must be operated intermittently to avoid overheating, as they usually do not have built-in vacuum cleaners and fans. The working period should not exceed 5-7 minutes.

At the initial stage of acquiring skills in performing hardware manicure, it is recommended to use the minimum rotation speed of the nozzles. In this case, you need to ensure that the nozzle is inserted strictly at an angle of 45, and the cutter moves from the center of the nail plate to its edges. You can work with one or two hands, the main thing at the same time is to ensure the clarity of the movement of the nozzle.

Hardware manicure must be performed in strict accordance with the established rules, necessarily step by step, which is determined by the instructions:

- thoroughly washed hands are disinfected;

- the existing decorative coating is removed from the nails;

- the cuticle is pushed back with a wooden stick towards the nail hole;

- side rollers and cuticles are processed using drums with medium hardness;

- the cuticle is lifted with a diamond needle cutter;

- a cone-shaped cutter is used to remove the cuticle, and a bullet-shaped cutter is used to grind it;

- palms and fingers are cleaned of dead cells with abrasive soft spherical burs;

- the nail plate is given the desired shape through the use of cylindrical or trapezoidal cutters;

- the final cleaning of the nail plate is carried out, and after it - the application of oil;

- after applying the oil, the nails are polished with a double-sided polisher;

- the fat-free nail surface is first covered with a base coat, and then with a finishing varnish;

- at the end of the procedure, a cream is applied to the hands and a massage is done.

Despite the fact that a hardware manicure has obvious advantages over a trimming one, you need to understand that the quality of a manicure is still largely determined by the qualifications of the master: you need to know which nozzles to use at a particular stage of work, at what time to change the cutters, carefully inspect the treated areas, follow the sequence of specific operations.

Do not forget that hardware manicure should not be done more than once a week. Another limitation concerns people with a thin nail plate: hardware manicure is contraindicated for them.

How to sterilize?

Hardware manicure involves the mandatory sterilization of cutters. In this case, it is necessary to disinfect the instruments in stages. Usually disinfection goes through 3 mandatory stages:

- immersion of instruments in a special disinfectant solution with their subsequent thorough washing;

- cleaning cutters from various kinds of contaminants;

- final sterilization of cutters by boiling them or by using concentrated disinfectants.

At each stage of sterilization, it is necessary to process the instruments carefully, strictly observing all the time and temperature parameters specified in the instructions.

Reviews

Anyone who at least once tried to do a hardware manicure, as a rule, does not refuse it later.The advantages of this procedure over the traditional one are obvious: it completely eliminates the possibility of injury and, at the same time, is performed in conditions that are comfortable in all respects.

An undoubted advantage of hardware manicure is also its wide functional range, which makes it possible to provide high quality manicure even if there are certain errors on the nails and skin of the fingers.

Currently, hardware manicure is considered not as a newfangled trend, but as a procedure demanded by modern life and determined by the priorities of a modern person. Today, well-groomed beautiful hands and nails are far from a luxury, but a tradition, indicating that it is important for a person to maintain their own health and ensure that their image meets the aesthetic criteria adopted in modern society.

Read more about choosing cutters for hardware manicure in the next video.